Erling Skaar, a noted vessel master and technical innovator in North Pacific fisheries and marine operations, and a man known for his strong principles on safety, efficiency, and resource conservation, passed away July 1 at age 80.

Skaar suffered a pair of strokes and died in Salem, Ore. after giving a robust performance at Sangerfest 2023, where he participated as a long-time member of the Norwegian Male Chorus of Seattle.

Skaar grew up in a family of mariners in Stavanger, Norway. Trained as a marine engineer, he worked a few years as a teenager aboard Norwegian freighters and herring vessels, and then emigrated to the United States at age 20 in 1962.

In the U.S., Skaar signed onto a Shell Oil exploration vessel out of Oregon, starting as mess man and rising to chief engineer aboard the 5,000-hp Cal Tide by 1965. At a dance in Seattle, he met Liv Jorgensen, another new immigrant who grew up near Farsund, in the south of Norway. The couple married in 1964. That summer, Skaar tried his hand at fishing salmon in Alaska’s Bristol Bay.

The lure of Alaska fishing took hold. Skaar left Shell in 1967 to fish for king crab aboard the F/V Foremost, then worked aboard a succession of vessels before acquiring his own. Naturalized as a U.S. citizen in 1968, Skaar settled in Seattle and joined Ballard’s Norwegian community, an engine of the nation’s rising offshore fishing industry in the North Pacific.

He fished salmon and served as a port engineer at False Pass and Port Moller, then crabbed out of Adak on the Kevleen K. Skaar trawled off Oregon and Washington aboard the Windjammer, and in 1970 he signed on with the Mar-Gun, working under the tutelage of skipper-owner Gunnar Ildhuso.

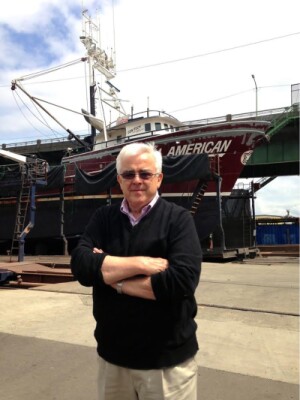

Spotting greater opportunities ahead, Skaar studied navigation at the Kildall School in Seattle. Upon graduation he signed on as captain of the Silver Dolphin, fishing king crab, tanner crab and blue king crab near Adak and the Pribilofs. Ready to run his own boat, in 1974 Skaar partnered with Ildhuso and New England Fish Company to commission a new Marco crabber, the North American. The 108-footer launched in 1975 with capabilities that were rarely seen at that time.

Skaar raised eyebrows on the waterfront by outfitting the North American with a Caterpillar 399, a 16-cylinder beast generating 1,100 hp, hundreds more than most crabbers of that era. That choice laid the foundation for some of his later innovations to improve the efficiency, safety and reliability of working vessels.

The extra horsepower positioned the vessel for multiple uses: trawling, crabbing, tendering, and research charters. It also enabled Skaar to run at low rpms to save fuel and reduce engine wear. Disenchanted with bottom trawling, Skaar refused multiple opportunities to convert to dragging gear, which he decried over concerns about bycatch and waste.

The Arab oil embargo of the early 1970s spurred a lifelong interest in fuel efficiency for Skaar. He installed a Flo-Scan fuel meter and trained his crew to use it to find the “sweet spot” for throttling down to near 900 rpm to save fuel. Later in his career, Skaar invented and brought to market an ultra-efficient system for generating onboard electric power for large working vessels.

In the 1990s Skaar pushed successfully for pot limits in the Bering Sea crab fleet, citing resource conservation and safety concerns. Skaar argued that a good living should be enough, and that setting too many pots meant losing more of them at sea, where they could continue “ghost fishing.” It made fishing more dangerous too, as crabbers were stacking the decks with destabilizing loads of pots, leading some to roll over with fatal results as fishermen raced to haul in the year’s available crab in a grueling “derby” season.

A firm believer in preventive maintenance, Skaar is remembered among crews for unstinting investment in safety and efficiency, and for embracing best practices aboard the North American. Erik Teevin, who served as an engineer and skipper on the vessel, recalls, “I told him one day, ‘We need another autopilot on this boat, the old one is failing.’

“Bang, $4,000 later, the new one was in. He told me, ‘We don’t cut corners.’”

Skaar enforced a no-smoking rule in the cabin and wheelhouse, and a strict clean-and-sober rule at sea. He was known for retaining loyal crew members over many years, in part by ensuring they were fairly paid.

Skaar managed the North American’s crab and charter operations throughout his life. By the turn of the 21st century he was also pouring his energy and savings into creating a novel fuel-saving generator technology, leading to the founding of GenTech Global from his office in Ballard. The GenTech system eliminated 75 percent-plus of the fuel consumption normally required to produce electricity aboard large fishing vessels, workboats, and yachts.

Skaar’s innovation met skepticism from some mariners because it revived the concept of a shaft generator, which others had tried with poor results, mainly due to inadequate control of power frequency. The earlier devices were blamed for fried electronics and more than a few lost tempers.

Skaar’s GenTech system brought unexpected reliability and efficiency to the shaft generator concept. To realize the elusive promise of harvesting surplus momentum from the main engine and shaft, Skaar stabilized power frequency using a software-driven controller developed by Norwegian engineer and scientist Odd Arild Olsen.

Skaar used the North American as a demonstration vessel, winning over early adopters in several fleets. Vessel operators reported that the GenTech system did more than produce reliable electric power and save fuel: it reduced maintenance costs in surprising ways. By replacing one of the auxiliary diesel engines that typically turn generators on large boats, the system eliminated many routine auxiliary-diesel rebuilds, avoiding a major expense.

By tapping a tiny fraction of the massive momentum from the bigger, slower-turning main engine shaft—and a smaller auxiliary diesel that induced its own field effects – the GenTech system yielded another unforeseen maintenance benefit: it slowed electrolytic corrosion, saving thousands of dollars in regular zinc replacements.

In 1980 Skaar started what some say was the first U.S. freezer-longline cod fishing operation in the U.S. North Pacific, outfitting the F/V Seattle Star (a converted U.S.-built icebreaking spy vessel) to catch, cut, and freeze the product at sea. Erling and Liv found themselves introducing the catch to West Coast seafood markets where “frozen” was still a taboo concept.

Fears of freezer burn and other quality concerns beset frozen fish in those early years, but the operation proved successful. As a fleet of much larger freezer longliners grew up, Skaar sold the Seattle Star, whose modest size and heavy hull eventually proved uneconomic. Freezer longliners now dominate the U.S. harvest in the nation’s last remaining major cod fishery (the Bering Sea), and the consistent, high quality of their product is respected worldwide.

Skaar was an early and steadfast champion for measures to cut climate pollution to protect healthy fisheries and ecosystems. In the 2000s, he took note when scientists reported that pollution-induced ocean acidification was killing off young shellfish along the West Coast, and that climbing temperatures had likely prevented recovery of New England’s depleted cod fishery and collapsed Puget Sound’s cod resource.

Aiming to protect fisheries from further harm, Skaar traveled to Copenhagen in 2009 for a UN conference on climate change, becoming an early leader among U.S. fishermen pressing to rein in pollution to defend their livelihoods. Starting in 2018, Skaar hosted a string of benefit events for the nonprofit Global Ocean Health aboard the North American.

Erling Skaar is survived and grieved by his wife Liv; sons Sten and John, daughter in law Anne and grandchildren Christian and Madeline, among other relatives; and by numerous friends and colleagues on the waterfront, in Seattle’s Norwegian community, and in Norway.