Steve Wessel of Wesmac Custom Boats, Surry, ME, has built several patrol boats for Maine’s Marine Patrol, but the latest is a different animal. “We’ve built at least three 46-footers for them,” says Wessel. But this one is 57 feet, and it has a Tier IV engine.”

According to Captain Colin MacDonald of the Maine Department of Marine Resources Marine Patrol, the service needs a bigger boat to deal with the changing nature of the fishery. “We needed a boat that could haul the bigger gear the fishermen are using. Our other boats couldn’t do it,” says MacDonald. This also gives us the capability to work in Area 3,” he says, referring to the waters roughly 50 to 200 miles offshore.

Wessel bid on the job and offered the Marine Patrol a 57-foot vessel. “There was a lot of back-and-forth,” Wessel says. There were some things they wanted in the layout. They wanted a steering station outside and aft of the inside steering station. That’s what they have in their other boats.” While the layout remained familiar, in a departure from previous vessels, the Marine Patrol wanted a much more powerful Tier IV engine.

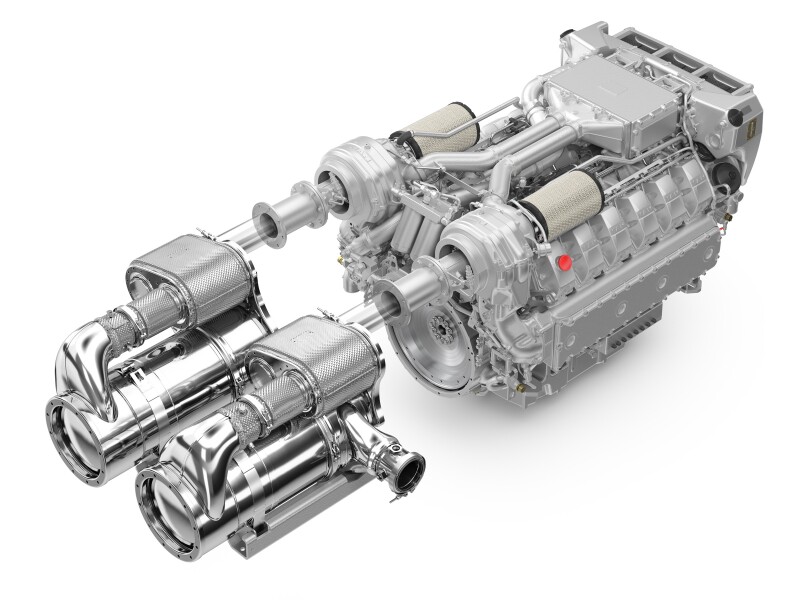

Billings Diesel in Stonington, Maine, supplied Wessel with a MAN D2862 LE48B engine. “It’s a MAN V-12 with 1450 horsepower at 2100 rpms,” says Wessel. “They slowed it down a little, used to be 2300 rpms. It’s Tier IV, so it’s got the after-treatment on dual exhaust.”

The MAN system uses an SCR (Selective Catalytic Reduction) catalytic converter to reduce the nitrogen oxides (NOx) in exhaust gas down to levels required by the EPA. MAN uses a 32.5 % urea solution (AdBlue©) that gets metered into an SCR mixer and continuously injected directly into the exhaust tract. “There, the solution reacts with the nitrogen oxides and converts them into water (H2O) and harmless nitrogen (N2). The compressed-air-free SCR injection brings further space advantages and reduces the technical effort and the installation volume of the system,” says the MAN literature.

“We went with the Tier IV because the current administration wants to move toward cleaner energy,” says Captain MacDonald.

According to Wessel, the after-treatment system is compact but not small enough to put on a working lobster boat. “If you needed to have a fish hold it wouldn’t work,” he says, noting that in addition to the 1500-gallon fuel tank, he also installed a 100-gallon tank for the urea, or DEF, used in the SCR.

The MAN V-12 turns a Twin Disc MGX 6620A gear at 2.09:1 and a 3-inch diameter Aquamet 22 shaft. “That’s high tensile steel,” says Wessel. “Otherwise, it couldn’t take it. I also use it in my rudder posts.” Wessel is putting a 38x38 propeller on the shaft. “It’s five-blade Nibral,” he says. “Bronze isn’t strong enough,” Wessel adds that he uses the Nibral, a blend of nickel, bronze, and aluminum, almost exclusively on his boats.

Although it won’t be fishing, the new vessel is equipped to haul gear. “It’s got a 17-inch Hydro-Slave hauler,” says Wessel, noting that the 18-foot beam will provide plenty of space to bring trawls aboard. The vessel will have an open stern to facilitate setting gear back.

“They’re set up to work offshore for four or five days,” says Wessel.“ They have a shower, a head, a full galley, and four bunks down below. Up in the cabin, there are settees who could sleep two more if they want.”

Wessel notes that the boat is about a third of the way done and should be launched in late 2024 or early 2025.