The need to reduce emissions from marine diesel engines has led to the Tier system in the USA and IMO ratings in Europe. Diesel engine manufacturers serving the U.S. market have engines with exhaust systems that drastically reduce NOx, CO2, and particulate emissions, but designers are also looking at the feasibility of alternative fuels. A study released last year in the UK delved deep into the obstacles to using Methanol and LNG on commercial fishing vessels, while in the U.S., Elliott Bay Design Group is applying for a grant to investigate the viability of alternative fuels for the commercial fishing fleet.

Mike Complita, VP of Strategic Expansion at Elliott Bay, realizes the challenges. “We have applied in partnership with the American Bureau of Shipping (ABS) for a grant to fund a study specifically relating to the safety of installing and operating these alternatives on U.S. fishing vessels,” says Complita. We have recently talked with a couple of groups about electric or alternative fuel power for the processing plant. This may take the form of an alt-fuel powered generator or reformers/crackers and fuel cells.”

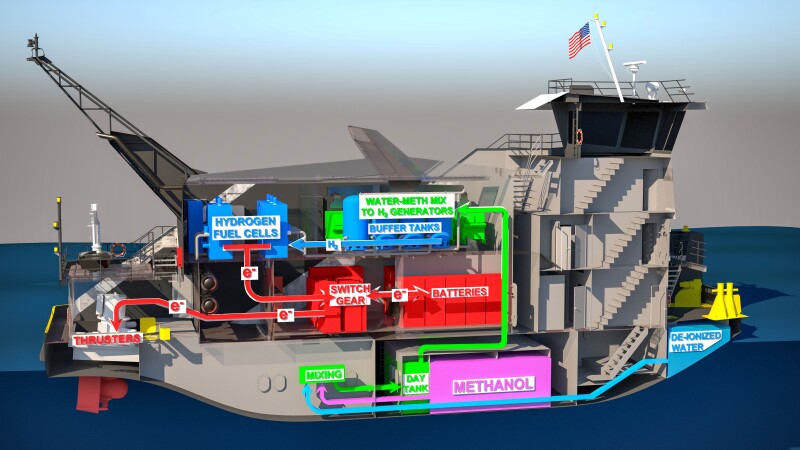

The technology remains complicated, not only in harnessing alternative fuels' power but also in fuel bunkering, transfer, and delivery. Complita points out that hydrogen, for example, requires a large storage capacity on board. “But when combined with methanol or ammonia as a carrier, you can actually store more hydrogen in a smaller space. Then, to access that hydrogen, you need a methanol reformer or ammonia cracker to release the hydrogen into a fuel cell to make electricity to run your processing or the vessel.”

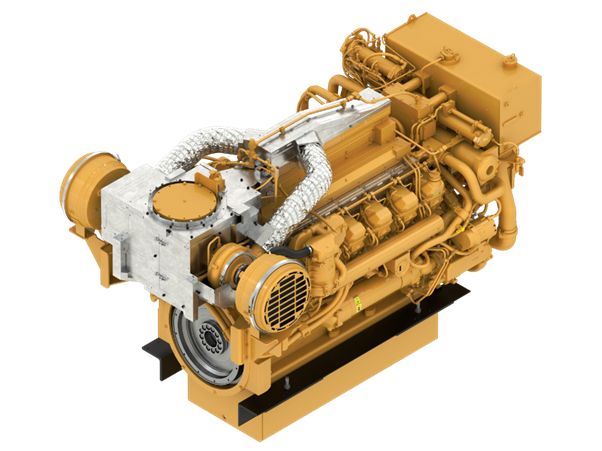

Complita notes that the other option is the direct use of alternative fuel in internal combustion engines. “Marine engine manufacturers such as Wärtsilä and MAN have engines on the market right now that can run on various other fuels, including methanol and LNG. In most cases, though, they still need to run some diesel in the mix, about 5 to 15 percent. But these are big medium and low-speed engines. Caterpillar is making a high-speed engine that is marketed as methanol-ready. It can be installed now to run on diesel and easily converted to methanol as the technology matures.” According to the Caterpillar website, the 800-hp methanol dual-fuel CAT 3500E engine will be deployed in a tugboat for field testing in 2026.

Getting this technology onto fishing vessels presents many challenges, the safety issue being just one of many. “We’ll hold a series of formal risk analysis workshops,” says Complita. “We’ll get everyone, engineers, fishermen, Coast Guard into the room and start talking about everything that can go wrong. Once we have considered all the risks, we will discuss and agree on the appropriate design and operation features to minimize them.”

Macduff Shipyards in Scotland released a report last year listing the many challenges to integrating alternative fuels into fishing vessel construction, including the need for larger vessels. Macduff estimated a 50 to 100 percent increase in cost, but Complita's experience with these technologies in other types of vessels indicates it may be higher. “Everything we’ve seen is a 250 to 300 percent cost increase,” he says, noting the higher costs of not only the engines but also the multiple additional safety systems. “This is primarily regulatory-driven, and we’re 20 years away from seeing many of these technologies ‘right-sized’ to be practical on fishing boats,” Complita says. “But right now, the technology for installing hybrid systems is available, and the costs are decreasing. If fishermen want to reduce both fuel cost and emissions, they have a number of viable options to do it now.”