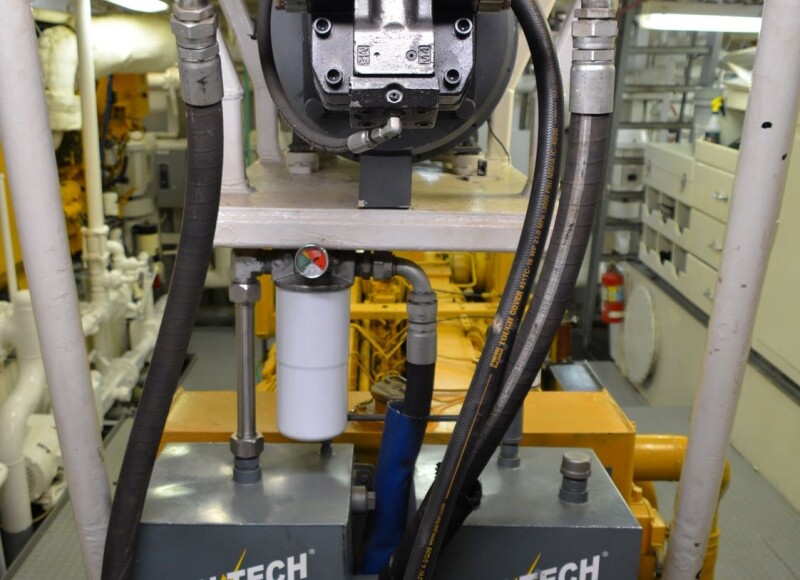

In 1973, during the Arab fuel embargo, the late Erling Skaar started looking for ways to conserve fuel. Thinking beyond the standard shaft-mounted or power take-off (PTO) driven generators, Skaar began designing a hydraulic-powered generator that could be driven off the main engine and retrofitted to various engines. It took forty years, but as technology improved, Skaar was able to utilize variable displacement hydraulics and solenoid flow controls to develop the GenTech system in which the main engine drives a hydraulic pump, which drives a hydraulic motor that drives a generator.

“The generator produces 50-60hertz at a given oil flow. By controlling the displacement of the pump, we can keep the oil flow at a set constant, independent of engine speed. Compared to other shaft generators, this dramatically saves costs in fuel and maintenance!” says the GenTech website.

New Bedford scallop fleet owner Dan Eilertsen put the GenTech system on two of his vessels, including the recently launched Vigilance, and has expressed satisfaction with it, noting that it delivers on its promise of fuel and maintenance cost savings.

MER Equipment in Seattle is a leading provider of generators to the commercial fishing fleet. MER’s CEO, Bob Allen, looked at the hydraulics option with Skaar many years ago.

“We went away from it because of the efficiency loss in conversion from mechanical energy to hydraulics and then from hydraulics to electricity,” says Allen, whose company is slated to equip a towboat with a variable-speed permanent magnet generator that will be directly coupled to the main engine with power conversion electronics. “With the recent advent of sophisticated inverter technology, our system gives up an equivalent of around 3% in conversion efficiency losses,” says Allen. While noting that the GenTech hydraulic system may be a good option for vessels with large hydraulic capabilities, he points out that the electronic method MER has moved on to is far more efficient and accurate regarding speed control, frequency, and voltage output.

“Our output is a true sine wave at 60Hz and +/- .5% voltage deviation from no load to full load,” says Allen. “Among other things, this allows us to parallel a diesel-driven generator with the inverter output to load share and peak shave. It doesn’t require bulky hydraulic lines, storage tanks, and hydraulic oil cooling systems. The moving parts are reduced significantly, resulting in lower maintenance costs and far better fuel efficiency.”

MER has partnered with another Seattle Company, ioCurrents to utilize Artificial Intelligence to further increase efficiency.