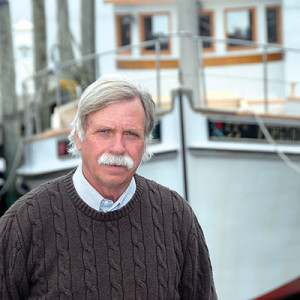

George Butler of Reedville Marine Railway in Reedville, Va., cannot seem to find a way to retire. For a while now, Butler has been talking retirement. However, there are still boats on the rails being hauled and maintained.

The 40' x 11.5' Glenna Fay and 48.8' x 13.5' Elva C. were on the rails in January. The Glenna Fay is owned by Reedville pound net fisherman Walter Rogers. Rogers is doing his own routine annual maintenance on the boat. He inherited the Glenna Fay from his father who had it built at the railway by George Butler’s father in 1947.

The Elva C. is awaiting the arrival of 2-inch-thick white cedar planks from John England of Urbanna, Va. Butler is going to install new side-planking on one side of the boat.

The Elva C. is owned by the Reedville Fishermen’s Museum and is used as an education boat. The deck boat was built in 1922 and worked in the pound net fishery for most of its working life.

One thing that keeps wooden commercial fishing boats and other wooden boats alive on the Chesapeake Bay is an aging boatbuilding infrastructure that still knows how to repair old wooden boats and lumberyards that cater specifically to wooden boatbuilding.

England purchases his white cedar from North Carolina and air dries it at his lumberyard in Virginia. The rough-cut lumber is milled to his desired width. The planks are flitch cut, also referred to as live-edge lumber, with the bark still attached to the sides.

England also sells white oak and spruce pine to boatbuilders. The time-length for air drying wood depends on the type of wood. White oak and spruce pine must be dried for one year for every inch of thickness, says England.

Two-inch-wide white oak planks require two years of drying. White cedar dries much quicker. Two-inch thick white cedar is usually ready in six months, says England. Butler is waiting for his white cedar to pass the moisture test. England uses a moisture meter to test his wood. The moisture level in the wood must be down to 15 percent for side and bottom planks.

England says kiln dry lumber is not the best wood to use for planking on old boats. “When the boat is in the water, you want the wood on the bottom and sides to swell,” he says. “Kiln-dry lumber dries the wood too fast and destroys some of the structure in the wood that hinders swelling.”

Moving to Poquoson, Va., blue crab fisherman Ken Diggs owns the 46' x 14.6' wooden deadrise workboat Miss Nina. The vessel was built in 1981 by the late Grover Lee Owens of Deltaville, Va.

Diggs is having father and son David and Nick Rollins of Poquoson rebuild the house/pilothouse, replace coamings, toe rails and washboards, and bulkhead aft of the house. The boat is also getting new wiring, and a new QSM11 Cummins diesel engine was recently installed.

Miss Nina was built for Diggs’ late uncle Ernest Diggs, and since the day it was launched has worked in every Virginia crab pot season. “We’ve got to have it ready by the first of March (opening day of crab pot season) come hell or high water,” says 70-year old David Rollins. Nick, 40, and his father are two of just a few talented wooden boatbuilders left on the lower bay who have generational knowledge of how to repair a wooden boat.

The Rollinses are also replacing mahogany tongue-and-groove strips on the back of the house/pilothouse with new mahogany strips. Since the late 1970s, some Virginia watermen have been using mahogany on certain places to brighten up their boats. The use of a well-maintained mahogany stern is a source of pride to some fishermen. Watermen also use mahogany in areas where there is little wear and tear, such as on the back of the house.

The new coaming, washboards and toe rails are made from white cedar. The house/pilothouse is made from white cedar and MDO plywood. The bulkhead, located just aft of the house, is made from salt-treated pine. The boat is fastened with stainless steel bolts and screws, and every joint is glued with the West Epoxy System, says Rollins.

The Rollinses are also repairing woodwork in Iva W. and Linda Carol, two Chesapeake Bay deck boats that have been converted to yachts. They are also working on a 70-foot tugboat named Captain Johnny. Three berths are being installed in the tug’s forepeak.

Although traditional wooden boatbuilding customs are waning in the South, there are still a few builders and lumbermen carrying on the trade.