Building his own jet seiner gives Thomas Lopez a leg up during tough times in Alaska’s salmon fishery. The limit seiner that launched into the Columbia River in Oregon in April 2024 is a first for Lopez, Owner/Operator of Apex Marine. “I’ve built other boats, but this is the first in aluminum and certainly the first jet-powered seiner,” says Lopez, who started the boat in January 2023 with hopes of getting it in the water for that year’s season. Supply chain issues led to the 2024 launch.

Working with his father, brother and others, Lopez has turned a couple of Gulf of Mexico mud boats into salmon tenders, and built a steel seiner, but his new boat is a twin jet powered aluminum seiner. “The fishery is changing,” says Lopez, whose family has fished Prince William Sound in Alaska for three generations. “My grandfather immigrated from Spain and built his first boat out concrete; it barely floated. Our family has come a long way since then, we all grew up around boats and we still see some of my grandfather’s later builds on the water. But traditionally these boats have been slow. If you were one place and the fish were someplace else, it didn’t make sense to try and move. I’ve been watching what’s been happening with the Bristol Bay boats, it’s all about getting to where the fish are fast. In the Prince William Sound whether it’s in a different district or someplace in the same district I want to be able to go after the fish. Like if I have to go across the Valdez Arm in my old boat, it will take 45 minutes. With this boat I’m hoping to do as much as 25 knots empty and make that trip in 10 or 15 minutes.”

To put the pieces of the puzzle together, Lopez engaged several people who brought something special to the project, beginning with Nick Boksa, president of Boksa Marine Designs. “Thomas had decided on all the mechanical systems. We designed the hull and structures for him—basically all the metal work,” says Boksa. “He wanted a boat that could go out fast and come back loaded, so we needed to find a planing hull and a displacement hull, and he needed maneuverability.”

While Lopez did the interior design, Boksa performed the weight study, hull form and stability analysis, and structural engineering.

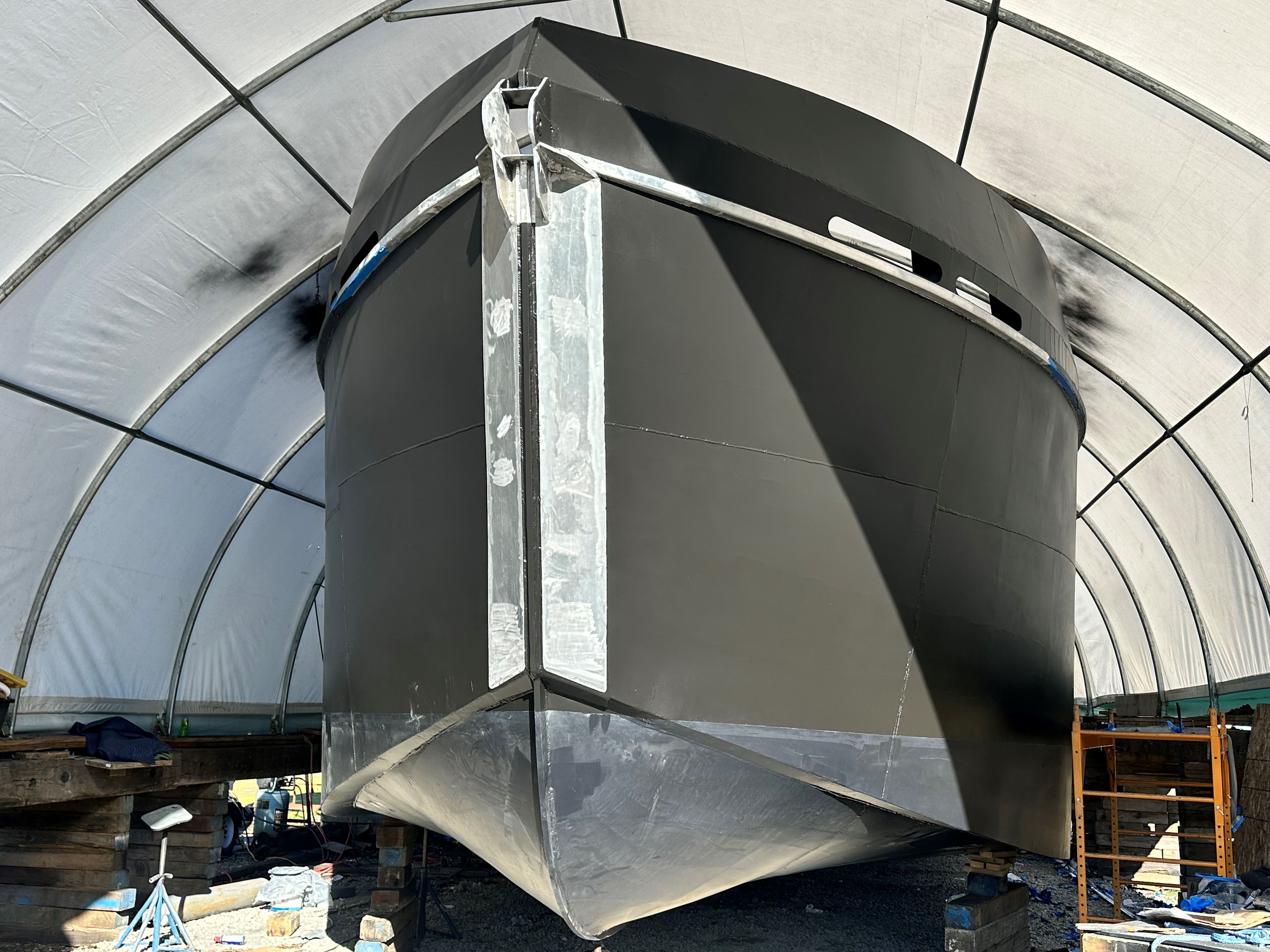

Boksa designed a hull that he and Lopez believe will achieve the desired performance levels. While Boksa designs steel and fiberglass boats, most of his projects are aluminum. “And aluminum is the best choice for this boat,” he says. “It’s light and strong. We did the bottom with 5/16-inch plate, 1/4-inch on the sides, and 3/16-inch on the pilot house. The deck is ¼-inch, and that’ll all be covered with a false deck.”

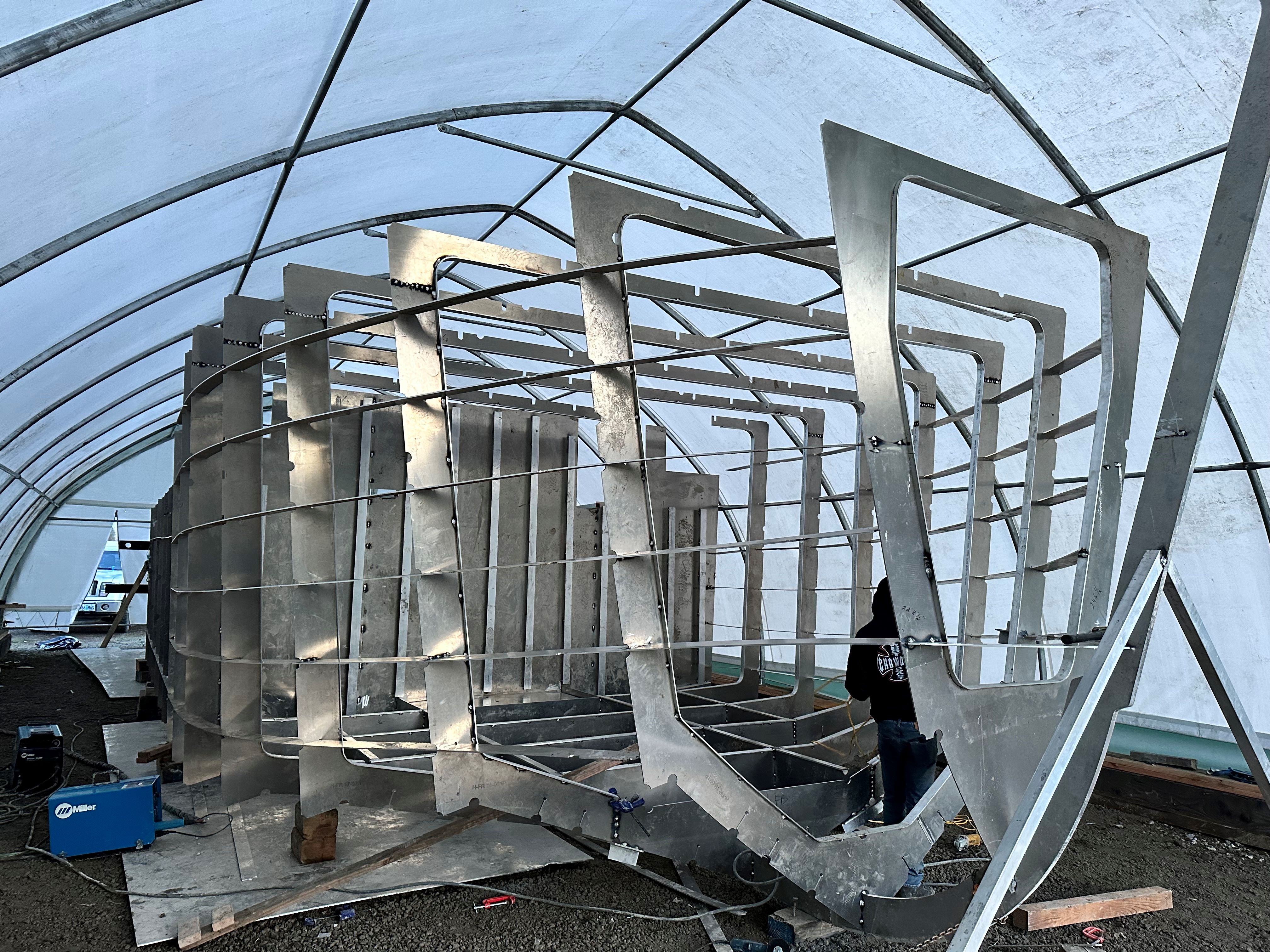

After finishing all the lofting and nesting of the aluminum plate in late 2022, Boksa sent the CNC files to Lopez. “He started cutting plate right away. He was on a tight timeline,” says Boksa. “We used ShipConstructor to create the files, it’s very precise. We don’t leave too much trim stock, just in places where there’s a radius and the aluminum has to be bent.”

While aluminum is lighter and stronger, it has properties that make it harder to weld. “You have to move your heat around or it can throw things off,” says Boksa. “What was lined up on one part might be 4-inches off after you weld another.” Boksa notes that while his company has designed many work boats, this is his first commercial fishing vessel. “We’d like to go deeper into that market,” he says.

According to Lopez, one of the biggest challenges was keeping everything aligned. “Once we got the deck plates down and had that perfect, the rest fell into place,” he says. “But as we welded, we constantly had to keep checking and tweaking to keep everything straight.”

With the frames set and much of the plate on the bottom, sides, and deck, Lopez installed the engines and jets. “I heard about FPT and they looked interesting,” he says. “I figured they would be out of my price range. But I talked to MSHS and the price worked. We went with the Cursor 9. They’re 620-hp each.”

“The C-9 620Es on Thomas’s boat include our dual circuit cooling system,” says Corey Lind territory manager at MSHS. The dual circuit system consists of a high temperature circuit for the engine itself, and a low temperature circuit for the turbo charger that will help keep NOX emissions within EPA standards. “And these engines are monsters of torque,” says Lind, noting that the company believes there is no better engine to give Lopez the torque, power density, and efficiency he needs.

Lopez and Lind matched the the FPTs with ZF360 gears at 2.185:1 that turn a pair of 18-inch, NAMJet, TJ-431 jets. “That’s our mid-size jet,” says Phil Organ, director of business development at NAMJet. According to Organ, the gear ratio is higher than normal for a marine jet because NAMJet jets are water mass flow jets. “They’re designed for high thrust at low RPMs,” he says. “They rely on high volume of water flow and are designed to carry heavy loads.”

NAMJet jets also differ from more conventional jets in that they use gates to control reverse and steering. “You don’t see a bucket and steering nozzle,” says Organ. “Instead, we use a set of gates, kind of like barn doors.” When the gates close, they reverse the flow of water coming out of the jet and put the vessel in reverse. For steering, the entire square unit that holds the gates turns from side to side.

“Another important aspect of our jets is that the housing is all aluminum,” says Organ. “So, you can weld it directly to the aluminum hull and mount it anyway you want.”

“Phil is one reason I went with NAMJet. He’s right there,” says Lopez, who has installed his jets flush with the transom.

Lopez is using custom made Italian winches on his picking booms. “I have two winches on each pick boom. A lightning fast one for ‘strapping’ fish aboard and strong one that could lift a skiff out of the water,” he says. “The strong one can lift 8,000 pounds.” Lopez will be using a 28-inch Marco Power Grip block and Kolstrand deck winch when seining.

The Waymaker’s 108,000-pound capacity is split been two holds that will be kept cold with a Cold Sea 25-ton, RSW (refrigerated seawater) system. “We still have to go down there and commission it,” says Cold Sea owner, Mark Bolinski. According to Bolinski, the 25-ton system uses an Italian-made Frascold compressor and requires a 28kW genset for power. Lopez has a 45kW genset on the Waymaker.

Wheelhouse electronics include a TimeZero Pro bottom building program with other add-ons. “For navigation he’s gone with the Garmin GPS map and a 12-inch multifunction display,” says Dave Reinikka, of MacKay Marine, which supplied the electronics package for the Waymaker. “He’s got the connected to the Garmin Fantom 24-inch radar. His sat-compass is a JRC model JLR-21, which we say, you set’m and forget’m.”

Lopez chose a Furuno sounder and Airmar transducer. For AIS he has a Comnav mariner X2 class B transceiver with an external GPS antenna. Other electronics include Glendenning controls, Standard Horizon VHFs, and a Standard Horizon 30-watt loudhailer. “Between Dave at McKay and Steve Brooks at SeaMar I’ve had the most incredible service from my vendors, they’ve truly been top notch. Steve made four trips down to the boat, he was determined to get my controls working 100 percent.”

For crew accommodations Lopez has a double bunk for himself in the wheelhouse, and bunks for 5 crew down below.

On April 16, 2024, Lopez trucked his new boat to the coast and splashed. “We’ve been working on getting all the electronics and controls figured out, and getting the rigging set up,” says Lopez.

While Lopez had planned to fish in Prince William Sound, a small projected run and low prices convinced him he’d be better off tendering in Bristol Bay. Where he built the boat himself, he feels he’ll have no issue weathering the difficult times of low prices and small runs easier than if he had to pay someone to build it. Tendering is just another of his options. “I’m not sure where we’ll be exactly, wherever our processor sends us. Where we only draw 18-inches, so I’m guessing it will be shallow.” Wherever he does go for fishing or tendering, he’ll get there fast.