Washington state-based Wesmar has been turning out solid, reliable, and powerful bow and stern thrusters for the commercial fishing industry for more than 55 years. Bryan Thiemann, Wesmar’s account sales manager for the United States, said the company’s longevity and reliability have made their products ubiquitous across the nation’s fisheries.

“If it’s a commercial fishing boat, it potentially has our stuff on it,” Thiemann said.

Part of Wesmar’s success comes from their unique design, Thiemann added.

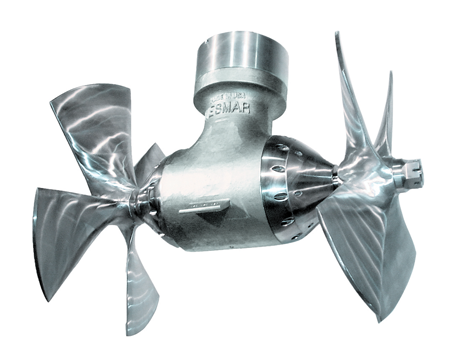

Each Wesmar thruster has two counter-rotating four-blade Kaplan propellers. The dual-prop system raises efficiency by splitting power between two different gear sets, and the wash from the forward propeller is picked up by the aft, creating greater thrust. Wesmar bow and stern thrusters run from 5- to 500-horsepower, and the effi-cient dual propellers add up to more thrust per horsepower unit. This means space savings on smaller boats.

“For instance, with the Bristol Bay gillnetters, which is a big market for us, they’re often very shallow-draft vessels, so they don’t have a ton of space for a bow thruster. The Wesmar allows them more thrust in a smaller profile tunnel,” Thiemann said.

Gillnetters, Thiemann said, typically use thrusters with 8-inch propellers, but Wesmar offers 12 sizes running all the way up to 48-inch propellers, covering a wide range of boats across many fisheries. Solid stainless construction has been another key to Wesmar’s presence in the fishing industry.

“All of our thrusters, bow and stern, are full stainless steel construction. It’s 305 cast. We have stainless housings, gears, bearings, props. Everything we do is commercial duty… and manufactured in the USA. We’ve been doing it since 1965, and we make quality products that are built to last,” Thiemann said.

Thiemann noted that thrusters that are 25 or 30 years old often come into Wesmar’s shop in Arlington, Wash., and need just a simple seal and O-ring service to get back on the water. According to Wesmar, they use “the highest quality seals to the input and output shafts to prevent water ingress and oil leakage.”

Service on the seals is simple because the the thrusters do not have to be taken apart to swap out seals.

Wesmar’s two-bolt drop-in design makes retrofits simple for metric tunnels, with a couple models that can easily replace Max Power, Side Power, and Vetus thrusters. All Wesmar thrusters can be run on on hydraulic power or a choice of DC 12-, 24-, or 48-volt power or AC variable speed.