With the help of Ampro Shipyard in Weems, Va., Omega Protein in Reedville is busy getting its menhaden fishing fleet ready for Virginia’s 2021 menhaden fishing season. The season opened in May.

Omega recently announced it’s cutting back on its Chesapeake Bay fishing fleet, as six boats will be fishing this season. Last year, the firm had seven menhaden steamers working Chesapeake Bay and the Atlantic Ocean.

The Tideland, one of the largest and oldest vessels in the fleet, will leave the fishing end of the business. It will remain in the fleet, however, as a carry-away boat. The 218-foot Tideland was launched in 1966. “She has caught a jag of fish in her lifetime,” said Omega’s Reedville Vessels Manager Harvey Hamm.

Tideland will require only a minor conversion to switch from fishing boat to carry-away boat. It will require installation of new pumps, modification of the hydraulic system and some new stainless steel piping.

The work will be done with the boat in-water at the Omega Reedville plant by way of a partnership between the Ampro work force and Omega’s boat maintenance crew. “We rely on Ampro to do a lot of our work,” said Hamm. “When we have a need we can count on them coming to our place to jump in and take care of the problem.”

The F/V Calcasieu Pass is at the Ampro Yard in Weems. It’s there for upgrades to fish screens and to the refrigeration system. The yard is also replacing black iron piping with stainless steel pipe and rusted out ladder steps. “We are just trying to bring her back to life,” said Hamm. “If we take care of small problems at the start of seasons, it helps to eliminate larger problems in the future.”

Omega’s F/V Fleeton was at the Ampro yard before the Calcasieu Pass arrived. Ampro installed several new bridge wing doors, modified some of the hydraulics and replaced iron piping with stainless steel.

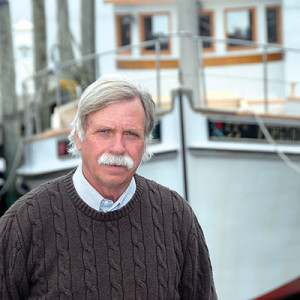

Over in Heathsville, Va., Chesapeake Bay pound net fisherman Fred Jett of Ophelia, Va., had his wooden pound skiff glassed at Cockrell’s Marine Railway.

Built by George Butler of Reedville in 2000, the 23' 8" outboard-powered wooden skiff has been worked hard in the Potomac River pound net fishery, and it took a major overhaul to get her back on the waves. The old paint, inside and out, was power washed off with a 7,500-psi sprayer. And the outside was completely covered with two layers of DBM 1808 Knytex Biaxial matt and woven.

The ribs and chine are supported with 3/4"-thick sheets of Carbon Cove Honeycomb, fastened with stainless screws, and the inside of the skiff is totally encapsulated in fiberglass.

Jett uses the flat-bottom skiff as his main fishing boat for most of the season and has a larger deadrise boat for setting and dismantling pound nets at the start and end of seasons.

Butler’s boatbuilding records show he delivered the skiff to Jett in October 2000. “I can tell you one thing,” says Butler, “Fred works his boats hard, and I know she needed a lot of something to bring her back to life.”

Cockrell says the oak ribs along the inside of the skiff were about gone. Shoveling fish out of the bottom had just about shoveled the ribs away, he says. “There was hardly anything holding the chine to the sides. We got her back together and I guarantee she will last another 20 years.”

Moving south to the Gulf of Mexico and to Omega Shipyard in Moss Point, Miss., Omega Protein’s Vice President of Fishing Operations Monty Diehl reported that the yard has a $7 million refurbishing project about to start on the menhaden steamer Frosty Morn. The vessel is owned by Omega and used in the gulf menhaden fishery.

The 195-foot Frosty Morn was built in 1958 for the menhaden firm J. Howard Smith by Bellinger Shipyard in Jacksonville, Fla. Frosty Morn started life fishing for menhaden off the New Jersey coast and has spent the last 50 years in the Gulf of Mexico’s menhaden fishery.

The yard also has a contract with its parent company, Cooke Aquaculture USA, to build a service barge to work in Cooke’s offshore Atlantic salmon aquaculture operations in Maine.

It takes three years for Atlantic salmon to grow to maturity. The first 18 months are spent on land at a hatchery, and the next 18 months in ocean penstocks. The service barge will be used at sea.

Omega Protein is looking for a used offshore support vessel for potential conversion to a menhaden steamer. “We hope to do the conversion at Moss Point in 2022 to have the vessel ready for the 2023 (menhaden) fishing season on Chesapeake Bay,” said Diehl.