Fishing Back When: Story and photos by Linda Skupien from the June 1987 issue of National Fisherman.

A new breed of fishing vessel could reportedly cut more than $50,000 off annual fuel and refrigeration costs for commercial shrimp fishermen.

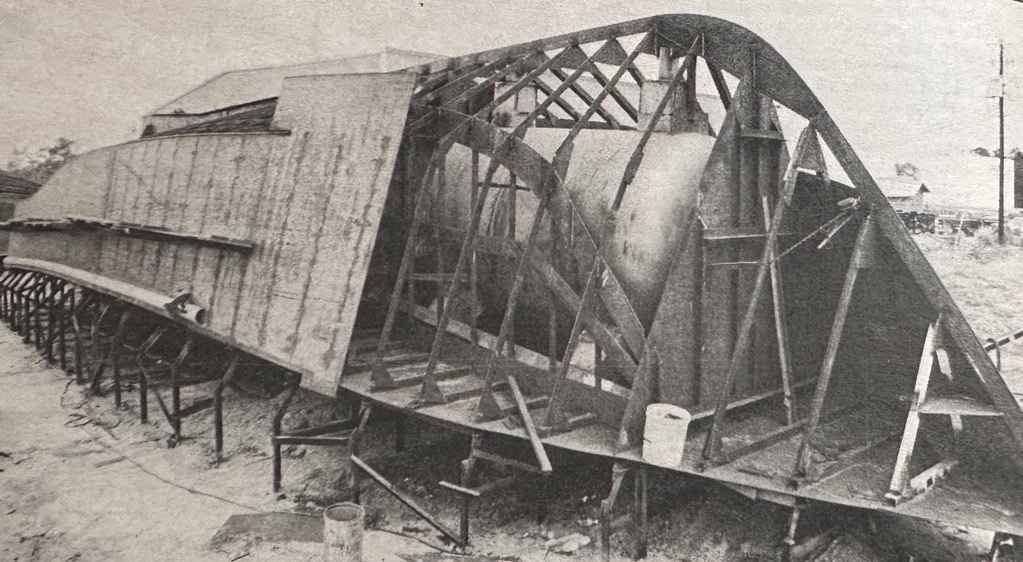

Recently completed at Bayou La Batre, Ala., boatyard and dubbed the MERV-1 (Methane Energy Research Vessel), the 70’ x 20’ x 10’ steel boat features an engine that has been modified to burn both methane gas and conventional diesel fuel. The work was carried out in a research project sponsored by the University of Alabama. Construction of the boat was supported by a variety of other agencies and private businesses.

The key to the potentially dramatic cost reductions is the use of methane in the form of liquefied natural gas, or LNG, according to project leader Dr. C. Everett Brett. “Currently,” he says, “LNG is about half the price of diesel; the nation’s methane supplies are abundant; and the prices don’t surge upward as a result of seasonal fuel use or international politics.”

In comparison, Brett says, current U.S. dependence on foreign oil (now up to 38% or more, compared to 34% just before the 1973 fuel crisis) has led to predictions of another, even more severe energy crunch in the near future. Such an event would again mean a bleak picture for the fuel-intensive shrimping industry.

“With their high operating costs, many U.S. shrimpers are already having difficulty competing against imports of shrimp raised and harvested with cheap labor in South American mariculture operations,” Brett says. “This project will lower operating costs to where shrimpers can be competitive in the international market.”

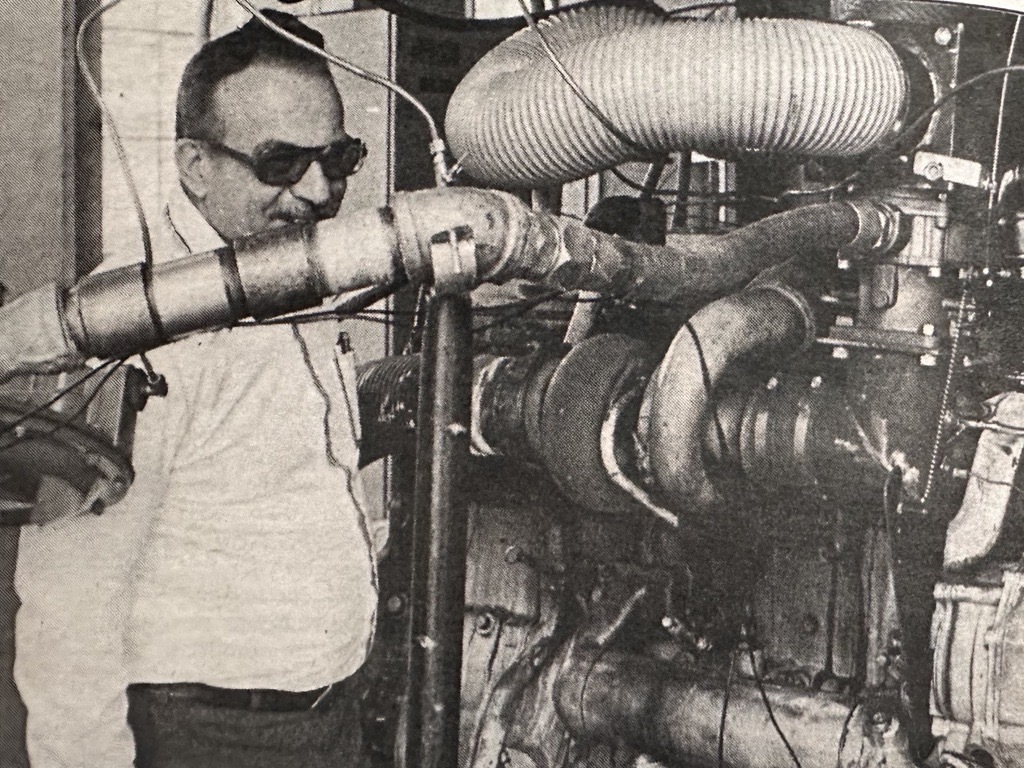

Brett’s team at the University of Alabama Research has spent three years working out design details for converting the diesel engines of shrimp boats to the dual methane-diesel fuel system. The setup they developed includes a methane carburetor on the engine, cryogenic (super-cold) tanks to store LNG at -260 degrees fahrenheit, a special fuel line system, a refrigeration system to use liquid methane’s potential for absorbing heat, and a heat exchanger to provide gaseous methane to the engine at a constant temperature. The Generator that provides electricity for electronics, pumps, and lights also runs on LNG, as does a conventional freezer for backup.

According to Brett, construction costs for an LNG vessel are comparable to those of any new shrimp boat, with the exception of the two prototype cryogenic tanks, which cost a total of $40,000. That price, he says, will drop when and if such tanks are manufactured in a production mode.

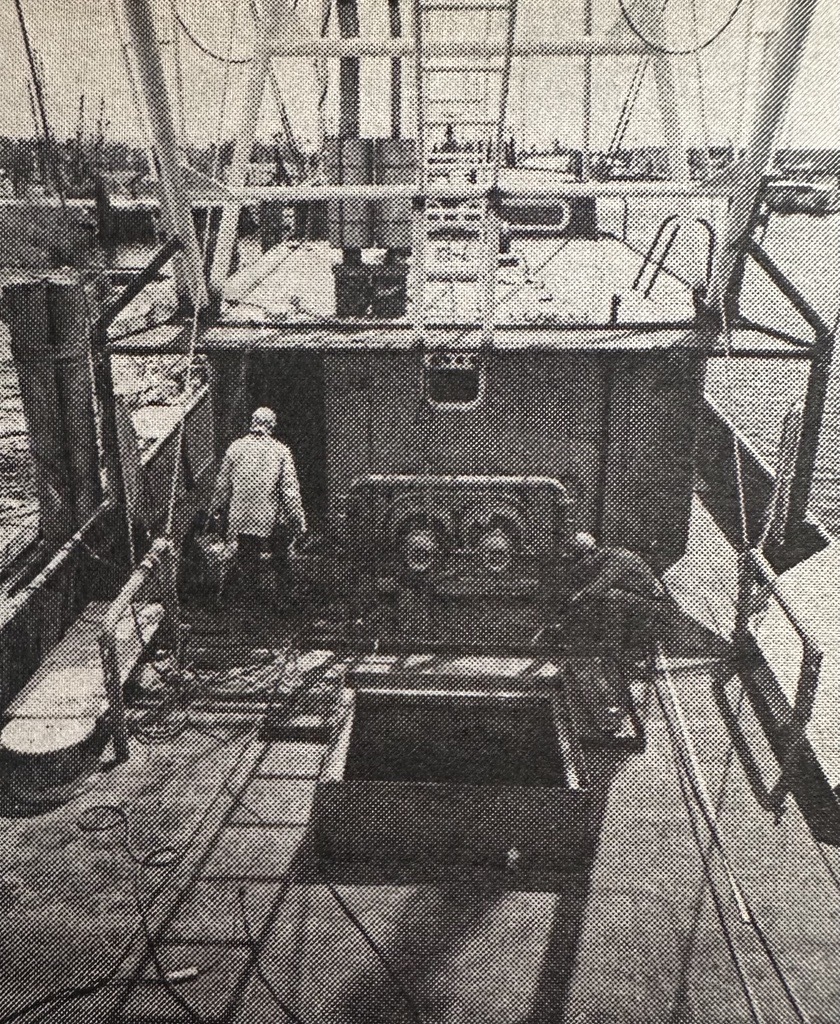

Using the MERV-1 in an actual shrimping operation this summer will put the researchers’ work to the test. “We’ll be taking numbers off the boat for at least a year,” says project engineer Walter Schaetzle. “An onboard computer will record fuel flows, engine r.p.m. and temperatures from 20-30 different sites in the system.”

If the economics of the MERV-1 check out, Brett and the research team will begin work on retrofitting an existing shrimp boat. With about 14,000 such vessels in the Gulf and South Atlantic fleets, that’s where the market is, Brett says. Retrofitting, however, is more complicated than new construction. Explains Brett, “There is the additional cost of hauling the boat out of the water; cutting the sides out in two places; installing the tanks, insulation and piping; and putting the sides back on.

“We are looking at $40,000-$70,000 to convert an existing shrimp boat. At 30%-45% savings on operations costs, the payback on the conversion ranges from less than once year to two years.” Brett says the greatest savings would be for a large ice boat that burns a lot of fuel and could benefit from a methane refrigeration system. The advantages would be less for a small boat that already has a freezing system.

The heart of the MERV-1 duel fuel system is the specially built carburetor. In a normal compression-ignition diesel engine, combustion occurs when fuel is introduced into air that has been compressed to high pressures and temperatures. These temperatures are not high enough, though, to ignite methane. Methane has a spontaneous ignition temperature of 1,184 degrees fahrenheit (compared to 536 degrees for diesel) and must be mixed with air at a concentration of 5%-15% methane.

But with its injectors serving as spark plugs, a diesel engine can burn methane. The carburetor that researchers attach their experimental power plant’s intake manifold mixes methane with air. Next, the mixture is moved into a cylinder in the same way that a spark-ignition engine inducts a charge of gasoline/air mixture. Then, a pilot charge of diesel initiates combustion.

“The amount of methane, you allow to go into the air intake controls the amount of power you get,” Brett explains. “The pilot diesel charge is held constant, and you use about ten percent of diesel you would use operating on diesel alone.”

With the flip of a switch, the engine can alaso operate totally on diesel, and the MERV-1’s diesel tanks hold enough fuel for use both as the pilot in the duel system and as emergency backup.

B&B International is the Italian company that provided the initial conversion kit and technicians to help install it. The firm's test results show that engines using the dual-fuel system produce more power at identical r.p.m. and operate at 23% higher efficiency than with diesel alone. On the basis of tests on Caterpillar 3208 and 3406B engines, the University of Alabama team expects a 15%-25% increase in efficiency and a 10% increase in available power.

Getting that kind of efficiency presented the project's researchers with several engineering challenges, among them the turbocharger on the 3406B Caterpillar engine for the new vessel. The team found that the turbocharger raised the temperature of air at the point of induction high enough to ignite methane. Because they were seeking highly controlled ignition, they added an intercooler (connected to an independent keel cooler) to bring down the temperature of air going into the system.

Storage for the experimental boat includes two stainless steel, cylindrical tanks - a larger one in the bow and a smaller one across the stern.

Understandably, installing these large tanks required some modification in the traditional Gulf shrimper layout. The forepeak area, normally used for net and gear storage, shrank considerably and the remainder was used to house a fresh water tank. The fish hold, too, had to be shortened by one frame's worth because of the mounting system on the forward tank.

According to the naval architects involved in the project, however, the fore and after tanks balanced each other well enough that their effect on trim was negligible, and no adjustment was made in the vessel's lines to compensate for her unusual tankage. Nor was extra weight a problem, for although the stainless tanks are heavy, the MERV-1's LNG fuel weighs 3½ Ibs./gal. vs. 6 lbs. for diesel.

The project engineers also developed special insulated mounts to eliminate the necessity of attaching the tanks to metal, which would conduct heat and increase vaporization of the LNG. These mounts are flanges welded to the top and bottom of the tanks and embedded in high-density poly-urethane foam. The polyurethane is linked to the boat's framing, and the tank compartment is then completely filled with low-density polyurethane foam.

"Our calculations show that we probably don't need the mounts," Brett says. "The low-density foam is adequate to hold the tanks safely in place even in the roughest weather, but we are including the mounts on this first boat for added safety." Together the methane tanks hold 4,768 gals. of LNG, enough for a two-week trip with a good margin of safety. The methane can be held up to seven days before vaporization begins. With the low pressure in the tanks, however, little fuel is lost through vaporization, say researchers, even if a boat is idle for several weeks. Moreover, project leaders report that a potential condensation problem on the surface of the super-cold tanks has been completely solved by the insulation used.

When the system is operating, liquid methane leaves the storage tanks at -260°F and goes into the refrigeration system. The methane then absorbs heat from the hold and the catch, warming up as it provides three tons of direct refrigeration, capable of maintaining a frozen catch at -10 °F.

The methane leaves the refrigeration coils in the hold at -10°F and passes through a heat exchanger that uses engine coolant to warm the methane to 60°F, at which point it moves to the main power plant.

Shrimp boat engines use enough LNG to freeze the catch or to keep it frozen - but not both. A backup freezer, a standard unit independent of the LNG system, will provide the capacity for quick freezing and for augmenting the LNG system if temperatures begin to rise when the main engine isn't running. "On later models," says Brett, "we will eliminate the freezer unit and use a waste-heat freezer developed and patented by Dr. Schaetzle."

To begin with, Brett emphasizes, methane is non-toxic and has an undeserved reputation as a dangerous fuel. He says it is extremely difficult to ignite in its gaseous state.

On the MERV-1, all spaces below decks are ventilated. Power ventilation automatically activated by a gas detector ensures that the mix of methane to air never reaches combustible levels. The LNG tanks themselves are equipped with two pressure release valves that allow venting when pressure reaches 60 p.s.i.

In addition to sponsorship from Sea Grant and the university, the project has attracted support in dollars, equipment or technical expertise from B&B Engineering, Bologna, Italy; Thompson Tractor Co., Birmingham, Ala.; Deep Sea Boats Inc., Bayou La Batre, Ala.; Alabama Gas Corp., Birmingham, Ala.; McAbee Construction Inc., Tuscaloosa, Ala.; Perkins Southern, Richland, Miss.; and the energy division of the Alabama Department of Economic and Community Affairs.