Nova Scotia has been on the path towards electrification of its lobster fleet since at least 2016, when the Nova Scotia Boatbuilders Association and researchers from the University of Victoria began studying the feasibility of using hybrid electric vessels in the fishery.

The team released its report—Characterization of Canadian Marine Vessel Operational Profiles and Hybrid Electric Propulsion System Modelling Tool Improvement for GHG and Ship Noise Reduction—in 2019, and more studies and research have followed.

In 2022, Oceans North, a Canadian charity that supports marine conservation and climate action in partnership with Indigenous and coastal communities, began bringing together the necessary partners to design, build, and demonstrate a vessel powered by all-electric propulsion technology in the near-shore lobster fleet. Joining forces with the Halifax-based naval architecture firm Allswater, which specializes in fishing vessels, Oceans North released its own electrification assessment in 2023.

"We wanted to find out if an electric vessel could perform in the fishery and meet the demands of the average operating profile,” says Brent Dancey, director of Marine Climate Action at Oceans North, noting that they wanted an economically viable vessel that could get the job done. “We don’t want to ask anyone to change the way they fish.”

Ocean North’s 2023 assessment began with a look at how much battery power a boat would need to fish for 12 hours a day. “The team’s analysis concluded that 70 percent of days fished by the entire fleet occur within 20 km of their home port, making almost 2300 lobster vessels possible candidates for electrification. Our assessment finds that 60 percent of these vessels could fulfill a day of fishing with less than 400 kWh of energy and are a great fit for battery-electric,” says the assessment, which goes on to note “that the typical size of many Nova Scotian inshore lobster boats could hold approximately 500 kWh of batteries and still have allowance for their catch weight.”

With prospects looking positive, Membertou First Nation, a Mi’kmaw community in Cape Breton, Oceans North, Allswater, and BlueGrid teamed up to assess the feasibility and design the first all-electric commercial lobster boat.

According to Rob Crutcher, president of Allswater, his company’s team designed a 45-foot Northumberland-style hull with a 15.1-foot beam, a relatively gentle sheer, and a flared bow. “We reduced the flare in the bow a little and created a hull shape that would move easily through the water and plane,” he says. “We tested it with CFD [computational fluid dynamics] models on the computer, and then it was tested at the towing tank at The National Research Council of Canada in St John’s, Newfoundland.” The result, he believes, is a more efficient hull that is ideally suited for electric power.

"An electric lobster vessel is the natural next step in our drive towards becoming leaders in the production and use of renewable electricity,” says Terry Paul, chief and CEO of Membertou, in a recent interview. “We see the adoption of battery-electric technology in the lobster fishery as an important step in developing a sustainable fishery that will benefit future generations. This first vessel will show fishers what’s possible and improve the work environment onboard by eliminating diesel pollution and reducing noise.”

In 2018, Membertou bought a boatbuilding and repair business in Sydney to maintain its fleet of a dozen or so vessels and build new ones, and has recently purchased another shipyard in Newfoundland. The electric boat project aims to advance new construction methods and build capacity to support Membertou’s boatbuilding enterprises.

"What a lot of people have talked about are conversions and retrofits,” says Crutcher. “But this is a purpose-built vessel. So, we can use the best materials to make it lighter and stronger and build it in a way that will reduce workers’ exposure to resin fumes.”

To improve the strength-to-weight ratio of the hull and structure, the building process calls for a vacuum infusion process in which resin is drawn into the dry stacked laminate under vacuum pressure. “This process allows for precise control over resin distribution yielding less imperfections in the laminates and improves the fiber-to-resin ratio compared to the traditional hand layup process,” says Crutcher, noting that since it is a closed-mold system, it prevents harmful volatile organic compounds (VOCs) found in most resins from escaping during the curing process which will significantly improve the air quality of the shop. “We can use lighter materials in the decking and cabin as well, which helps make up for the weight of the batteries.”

Dancey adds that boatyards are having a tough time finding workers. “By building the boat of the future in a shop of the future, we hope the industry can attract more workers,” he says.

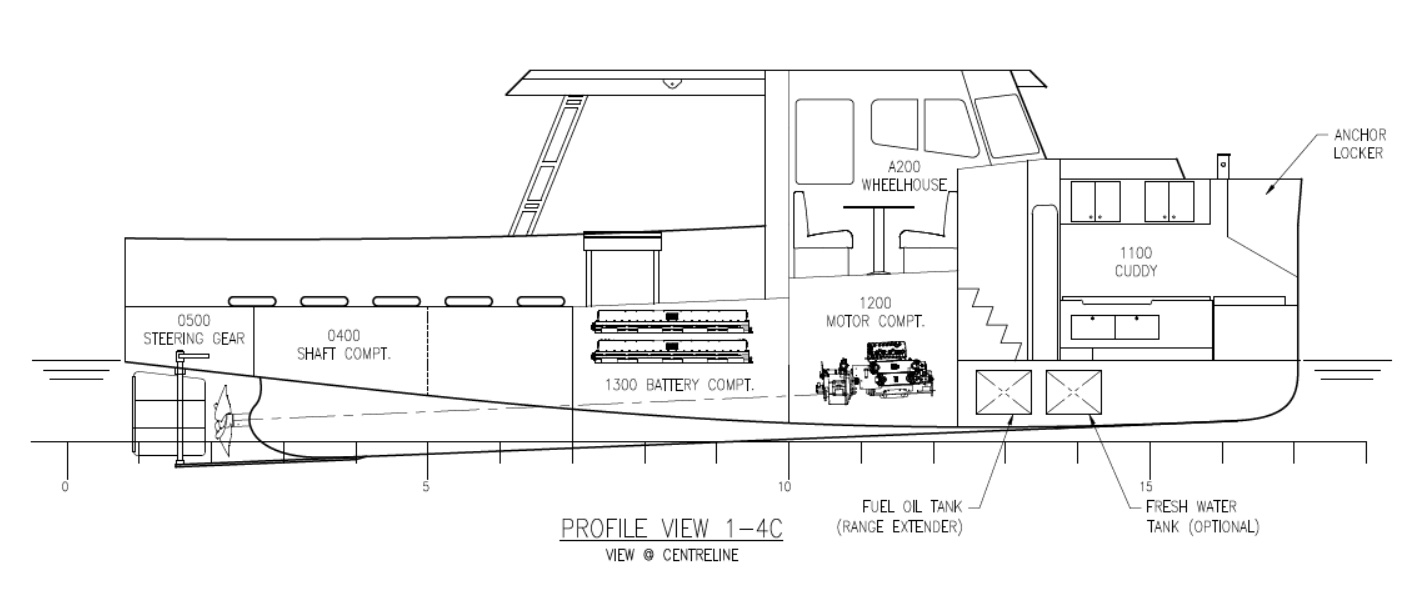

A Norwegian company, Evoy, will provide the batteries, electric motor, and power train. “We’re not going to try and invent an electric propulsion system,” he says. “Why do that when a perfectly good and proven system exists.” Evoy will provide the complete power package, including a 350kW electric motor and a 552kWh battery bank.

"The motor will be under the wheelhouse as in a regular lobster boat,” says Crutcher. “The batteries will be amidships. There will also be a small 25kW diesel generator for backup and emergencies.” Crutcher notes that the shaft will be a bit larger in diameter than on a diesel vessel of the same size and power in order to handle the full torque of the electric motor. The trap hauler will either be fully electric or electric/hydraulic. “Our goal will be to minimize the use of oils onboard,” says Crutcher. But the final arrangement will be developed to suit the fisher's preferences.”

"We have designed it for a top speed of 15 knots, although the model testing has been at higher speeds,” says Dancey. “But cruising speed will match the current diesel boats at around 12 knots, and most of the time, the vessel will be idling when hauling traps.” Dancey believes the electric boat will easily match the performance of a diesel boat. “Whether fishermen adopt the electric boat will come down to dollars and cents,” he says.

On that score, Dancey notes that while the upfront cost of an electric lobster boat will be higher than the cost of a diesel vessel, the lower operating costs will balance that out, and over the course of 20 years, the vessel will have cost about the same. “But with electric, there are social benefits like eliminating diesel fumes that have been linked to heart disease and cancer,” Dancey says. “You’re also reducing noise and vibration and creating a better work environment, which will be cleaner. You won’t have the mess of oil.”

In addition, he notes that the BlueGrid charging system will be bidirectional. “That means that while these vessels are idle in the offseason, their batteries can feed the power grid during peak usage.” As is the case with demonstrations that are happening with buses, there is the potential that power utilities will pay boat owners for the ability to store energy in the boat’s batteries. The incorporation of vessel-to-grid technology is an important design feature because it could unlock additional revenue streams for boat owners that will help offset the higher upfront costs of purchasing an electric boat.

The project team is currently finalizing a plan to build and pilot the electric boat. Once the construction details are settled, Crutcher and Dancey hope to be doing sea trials with the new vessel named the Lektrike’l Walipotl by 2026. Success, they hope, will usher in a new age for Nova Scotia’s lobster fishery.