When it comes to fishing vessels, crew comfort has come a long way since boats crammed a dozen or more men before the mast, but galley design remains outside the usual service offerings of naval architects.

“We don’t do the galleys,” John Waterhouse of Elliott Bay Design Group told NF. “There are people who specialize in that, and we contract with them.”

Fred Lillian, president of Galley Design and Sales, is one of the designers that Elliott Bay Design Group contracts with. He has turned galley design into a multifaceted form of applied art.

“The galley is really the heart of the ship,” Lillian says. “The engine keeps the vessel going, but the galley keeps the crew going, and fishermen work hard. While a normal person might consume around 2,000 calories a day, someone coming in off deck can consume as much as 8,000 to 10,000 calories a day.”

While galley design is sometimes seen as out of the norm for naval architects, Lillian reveals the complexity and importance of a well-laid-out food storage, preparation, consumption, and clean-up system.

“Generally, the designers will give us a space, and we have to work with it,” says Lillian. “There are so many things to consider in vessel design, that we don’t push back against that.” Lillian and his team just get down to the business of designing a plethora of integrated systems that make up the galley.

“The galley is like a little factory,” Lillian adds. “It is the heartbeat of the ship. We look at crew size and the average duration of a trip. Then we start thinking about bringing food aboard and breaking it down for storage. Because it all has to come back out again.” Additionally, Lillian considers where a boat is being supplied and how the food arrives.

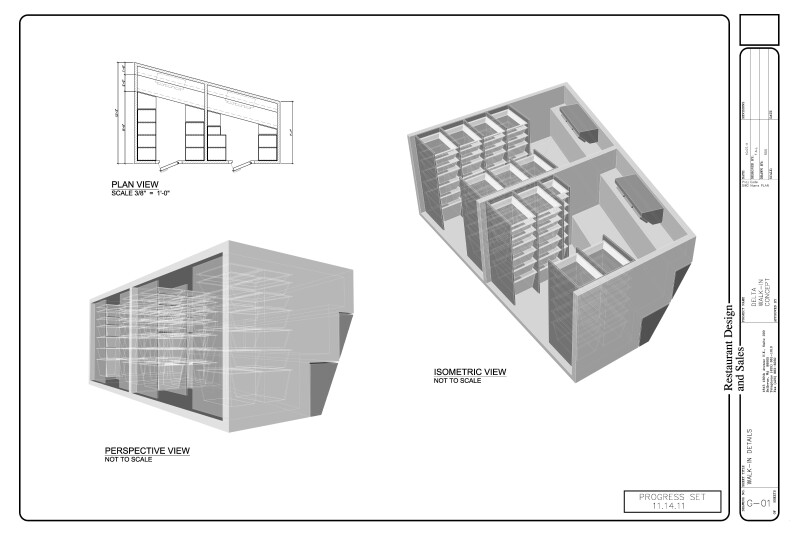

“We have to get creative with space,” says Lillian. “For example, sometimes the footprint for a cooler and freezer space might have an acute angle so that it’s something like a 4-foot reach into a corner. Food can get lost back there.” Lillian has designed a step system that conforms to the outer shape of the hull and provides easy access to all areas of the cooler and freezer units. “We use the space for bulk meats, and things like that,” he says.

Lillian has designed a container system for the bulk storage areas — dry storage, cooler, and freezer. A series of racks with see-through trays enables chefs and their support staff to access what they need when they need it.

“It allows them to practice the best protocols,” says Lillian. “First in, first out, so that food does not get lost in the back of a bin.” While Lillian designs the storage spaces, they are manufactured by outside contractors that he works with.

With food storage covered, Lillian and his team move on to the food preparation areas.

“There’s two types of cooking,” says Lillian. “You can cook large quantities to deliver to a buffet, where the crew gets what they get; or a short-order style, so if you want a burger, you can order a burger.”

The galleys Lillian designs contain grills, hotplates, and microwaves, but the one piece of equipment he believes every galley should have, is a combi-oven.

“The combi-oven is smart technology that cooks in three modes,” he says. “It’s like your oven at home: You turn it up to 425 degrees, and it gets hot. It has a fan in there that makes it a convection oven which is better for baking, but you can also cook with steam. It can cook in all three modes or any combination of those. You could broccoli, rice and a protein on different shelves and have no cross contamination of flavors and have each one come out perfect. And it’s simple.”

Lillian notes that he has to think vertically, as well. “Ceiling height is important,” he says. “You really need 85 inches, or it limits what you can put in there for equipment.”

Lillian also designs for the flow of food to the crew, and dining.

“The galley is the crew’s comfort zone,” says Lillian. “They may only have 30 or 40 minutes to get their food and eat it, so if we can make that easy it helps retain crew.” Lillian recommends what he calls a scatter system buffet, where if there is a line at the hot entrees section, there are other sections for salad and drinks, respectively, and crew can get what they need there rather than waiting in one line to access everything.

Lastly, a galley needs easy cleanup, and Lillian uses fairly standard systems where crew pass trays of dirty dishes through a window into the scullery section of the galley.

Among the challenges of putting a galley together is the engineering of all the systems, particularly electric and plumbing.

“We have to calculate every device and its power requirements,” says Lillian. The process of designing and refitting a galley can take as much as nine months, Lillian points out. “That’s why we like to have a master plan, so we can work on the project over several periods when the vessel is in the yard,” he says.