Rising from the ashes of their fiberglass boat shop, Ivan Basargin Sr. and his sons have turned to aluminum.

The fire at Basargin Boats in Homer, Alaska, in 2020 took everything. “All our molds, all our tools,” says Ivan Basargin Sr. “We had some boats we were working on in there.”

Ivan Sr had been building and fishing fiberglass boats for decades. “I started working with my uncles,” he says. “When we finished building their boats, they all went fishing. I had to build my boat with just my little brothers to help. That was 1989, I was 19.”

Ivan Sr. founded Basargin Boats in 2009, alongside his brothers and sons, Ivan Jr., Greg, Daniel, and Max. They built their first mold from scratch in 2009 and used it for Ivan Jr.’s first boat. “Mine was the second one out of the mold,” he says. “I was 19, like Dad.”

Since then, the Basargins have worked with their father, building around 34 boats of their own distinctive design, refining the lines, and building new molds over the years. “We’re fishermen and boat builders,” says Ivan Sr. “So, we’re always trying to make our boat better.”

The Basargin boats have an imposing look, with tall freeboard, tall pilot houses, and reverse-raked windows. “The Russians,” was all my son said when he first went to Bristol Bay at 17. And the way he said it— awestruck by the boats and the long-bearded men who fished them—was all you needed to hear to get the picture.

But when fiberglass meets fire, the heat and dense black clouds of smoke are also awe-inspiring. The devastation was complete, but the tragedy did stop the Basargins from building boats. “Everything was gone, so we switched to aluminum,” says Ivan Sr. “We worked with a marine designer in Washington, Sean Digaetano. He had helped us with the first boats, and he sent us back all the CNC files for an aluminum boat that is pretty much like our fiberglass boat.”

Switching from fiberglass to aluminum compelled the Basargins to develop an array of new skills. “We had a lot to learn,” says Ivan Sr. “The aluminum bends with the heat of welding, and it distorts the shape. We hired a guy who was very good at welding aluminum, and the guys at Bay Weld Boats here in Homer helped us a lot. So eventually we learned. We’re all welders now, Max and Jr. are probably the best, with the others right behind them.”

The Basargins have built two aluminum Bristol Bay boats so far, and three customers have built the design themselves. “We invested in some design software for Max, and he is working on our new sports boat lineup, like the Akula that we just built. “He creates the CNC files, and we send them to a CNC shop that we like in British Columbia—CJM Technologies,” says Ivan Sr.

In British Columbia, CJM nests the parts on the aluminum plate, cuts them, and puts them onto pallets. “From there, they send them to Seattle, where they put them on a ship to Anchorage. “Some of the pallets are pretty long,” says Ivan Jr. “But they figure it out. From Anchorage, we truck them down here.”

The shipping costs about $6,500 per boat and takes a month, Ivan Jr. notes. “The only problem is if there is a piece missing or a piece that doesn’t fit. It takes another month to get the new piece. So, we’re going to get our own small CNC machine to deal with that.”

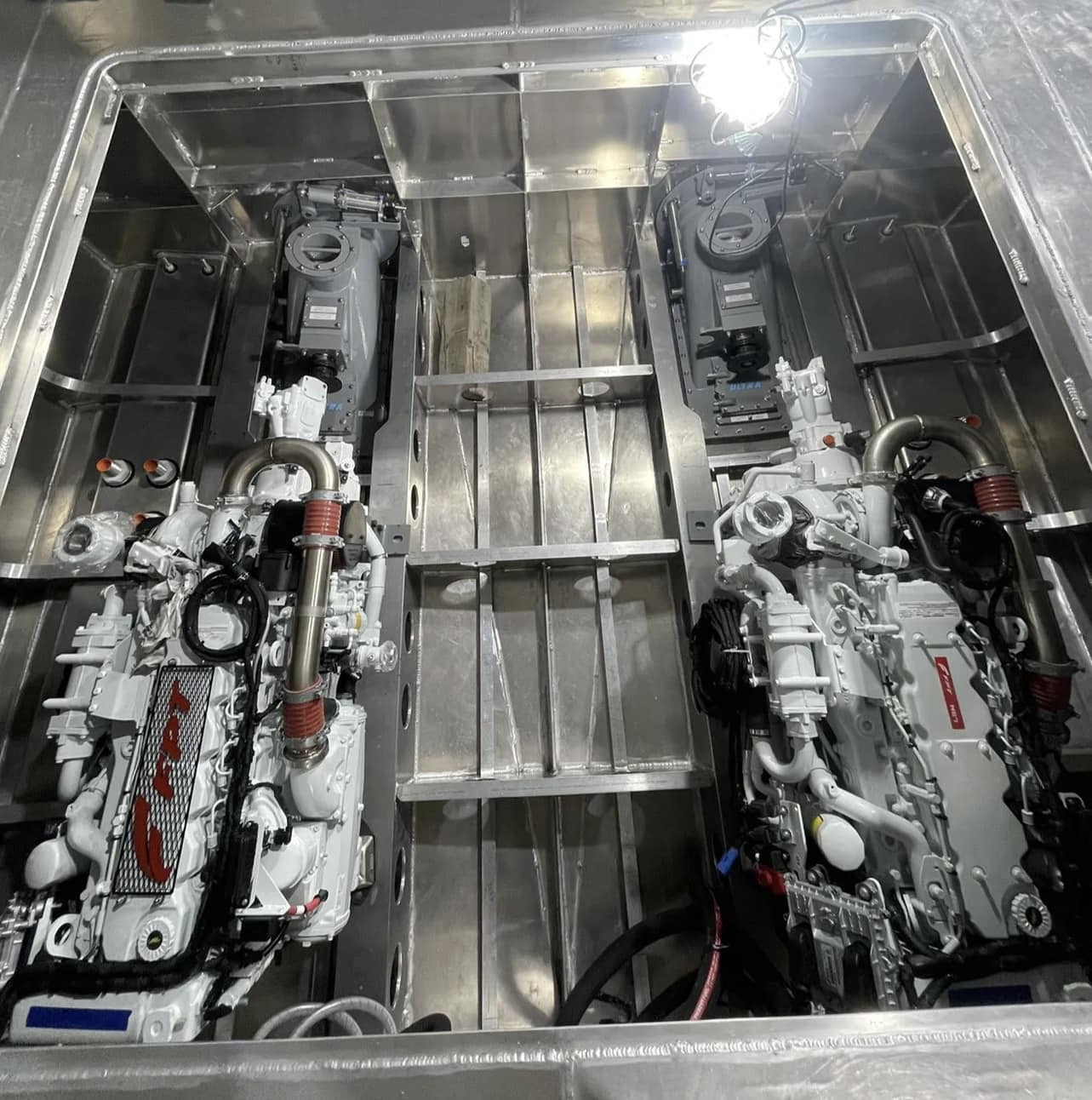

While the Basargin’s aluminum Bristol Bay boats look very similar to their older fiberglass models, the new material has enabled them to some changes, enabling them to put more boat into the 32-foot maximum for the bay. And where their fiberglass boats were propeller driven with a Cat or Cummins engine amidships, separating the fish holds, Ivan Sr. put a pair of 530-hp FPTs aft in the Top Notch, each with a Twin Disc 5075 gear and Ultrajet 340HT jet.

“The jet boat draws about 24 inches,” says Ivan Jr. “The others have a 28 to 30-inch propeller and draw 32 inches. A lot of guys like the propeller because they can go salmon fishing and then go longlining black cod and halibut. That’s what Dad used to do, but with the new boat, he has someone else fish his halibut pounds.”

Although many Basargin boats have been equipped with IMS refrigerated seawater (RSW) systems, for the Top Notch, Ivan Sr. opted for a 10-ton PacWest RSW. “I like the ease of use. I don’t have to make adjustments on it,” he says. “And the PacWest has a keel cooling option that I really like.”

For deck gear, the Basargins have used all the most popular brands on their boats— Kinematics, Kolstrand, and Maritime Fabrication. “I have Maritime Fabrication on the Top Notch,” says Ivan Sr. “They make a super nice anchor winch that I can lower and raise the anchor from the cabin. They made my reel and stern roller too.”

The Top Notch also has an arc of aluminum pipe over the fairleads on the stern roller. “Dad saw it on a boat back in the 90s,” says Ivan Jr. “We all have it on our boats. We put that there, so the tow line doesn’t catch the stern rollers when you’re holding gear in the water. The tow line is attached to the mast. It saves the crew from running back and forth jumping the tow line each time the boat turns.

The ample freeboard on the Basargin Bristol Bay boats gives them plenty of space for loading up with sockeye salmon. “The Top Notch holds 20,000 below deck,” says Ivan Sr. “But I once had 30,000, and 25,000 a few times.”

To handle those big days, Ivan Sr. takes as many as four crew. “I have four bunks down forward, and a daybed in the cabin for me.” Like Ivan Jr. and his other sons, Ivan Sr. starts the season with two crew, flies out another one or two for the peak, and then goes back to two at the end.

The Bristol Bay sockeye season usually starts in July, and the Basargins have two choices to get their boats to the remote harbors of western Alaska. They can go around the Alaska Peninsula one way or another—under their own power or on a barge—or they can take the boats across Cook Inlet to Williamsport and have them trucked over the mountain passes to Iliama Lake and then descend the Kvichak River to the Bay. They take the shortcut of the mountains “Our boats are 15 feet wide so they can make it over the bridges,” says Ivan Sr. “There’s not a lot of room, inches, and the boat has to be completely straight on the trailer, if it’s off a little it can be a problem.”

Heading far from affordable groceries, the Basargins like to put ample food storage on their boats. “We are out in Bristol Bay for a month,” says Ivan Jr “There are stores in Dillingham where we can get some stuff, but we like to take as much of our own food as we can. So, we put 5 to 7 cube chest freezers on the boats and fill them up with groceries.”

Up in the top house, the Basargins install the basic suite of electronics for boats fishing close to shore. “For electronics we like Garmin,” Ivan Jr. says. “They work well for us.” He notes that like their other boats, the Top Notch has the GPSMAP8616XSV plotter sounder, and the GMR Fantom 18X Radar, Black, among other electronics. Ivan Sr.’s boat also has a GC200 Marine IP Camera system for added safety.

“We also use the Bristol Maps app,” says Ivan Sr., noting that the app shows up-to-date satellite images of the bay and gives him the ability to add all the boats in his group to the map. “The satellite images are dead on. We love that app,” he says.

Having brought their aluminum boat-building skills up to par, the Basargins will continue to fish and build their impressive boats. As they fly across Bristol Bay at 28 knots or more and maneuver for fish, greenhorns looking on will drop their jaws and say, “the Russians” in that way that says it all.