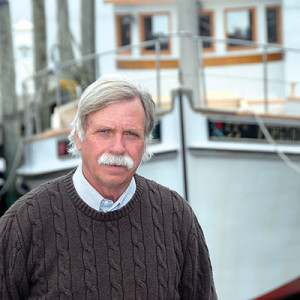

Joey Miller of Sinepuxent Boatworks of Berlin, Md., continues to turn out boat after boat inside a chicken grow-out house that he uses as his boatshop.

Throughout the south and over the years, this NF reporter has covered commercial fishing boats being built in deserted fertilizer plants, abandoned oyster shucking and vegetable packing buildings, seine storage sheds, Quonset huts, hay and tobacco barns, inside the family car garage, and under the sky in the backyard. A chicken grow-out house is a bit different but it just goes to show a good boatbuilder can build a quality boat most anywhere.

In August, Miller delivered a 22' x 9' glass-over-wood deadrise skiff to Matt Strong of Chestertown, Md. Strong is working the skiff in Maryland’s blue crab trotline fishery and to harvest catfish.

The keel and frames on the skiff are made of fir, and frames are set on 20-inch centers. The sides are strip-planked with 1-inch-wide juniper fastened with stainless steel ring shank nails driven every 8 inches. The bottom is made of 1/2-inch fir plywood, and bow deck and washboards out of 3/4-inch fir plywood. The bottom is glassed with 1708 biaxial fiberglass cloth and epoxy. The bow deck, washboards and floor (ceiling) are glassed with 1-1/2-ounce mat and epoxy. Miller delivered the boat unpainted as Strong finished off the skiff himself. The boat is powered by a 90-hp Suzuki outboard.

At his shop, Miller currently has 25-, 30- and 32-foot deadrise boats underway for sport fishermen. “I’m seeing more demand for sportfishing boats than commercial fishing boats,” says Miller. “I’m a former commercial waterman. I know their challenge. I wish more commercial watermen could afford new boats.”

Myles Cockrell of Cockrell’s Marine Railway in Heathsville, Va., has several commercial fishing boats at his yard there for repair and has an order to build an aluminum “davit” fish bailer rig for a pound net fisherman.

A Cecil Robbins-built fiberglass 29-footer is inside Cockrell’s boatshop for repair. Before retiring from the trade, Robbins built quality wooden and fiberglass boats in the late 1990s at his shop at Drawbridge, Md. The Robbins 29 belongs to waterman Jimmy Foster of Virginia’s Northern Neck. He had Cockrell reduce the engine box size and repair the Cummins Diesel engine.

To reduce the size of the box, Cockrell had to reconfigure the exhaust system. A large portion of the exhaust was mounted above the floorboards (ceiling), which limited floor space and got in the way of work and storing payload. Cockrell, using fiberglass conduit elbows, reconfigured the exhaust so it is now located below the ceiling. “This enabled us to open up more floor space and shorten the engine box, which gives Jimmy more workspace inside the boat,” says Cockrell.

Foster uses the boat, named Addy G., to fish crab pots and dredge oysters. The boat is powered by a 270-hp 5.9BTA Cummins Diesel engine. Cockrell is installing six new fuel injectors, rebuilding the injection pump and installing a new fuel lift pump.

Inside the yard’s covered railway is the sailing skipjack Claud W. Somers owned by the Reedville Fishermen’s Museum of Reedville, Va. Cockrell installed two new bottom planks on the boat and shored up the area around the mask for an upcoming U.S. Coast Guard inspection.

The Claud W. Somers, built in 1911 at Young’s Creek, Va., by W. Thomas Young, is used by the museum to carry charters and as an education boat. It was named to the National Register of Historic Places in Maryland in 1985 and in Virginia 2005.

Pound “trap” net fisherman Thomas Gaskins of Northumberland County, Va., has an order for a new aluminum “davit” fish bailing rig. The new one will be modeled after one made of steel that Gaskins is currently using. Chesapeake Bay trap fishermen use a variety of one-off bailing systems to bail fish out of the head, or main fish pocket of the net.

Variations of hauling systems, usually powered off main engines of boats, are used to lift heavy dipnets loaded with fish from the pound net head and then dropped into the bottom of a carry-away boat.

On a final note, Edward Nelson Diggs of Mathews County, Va., died on Nov. 26 at the age of 93. One of the last of Virginia’s old-time wooden boatbuilders, Diggs’ first recollection of being a part of the trade was as a boy in early 1930s, where in his backyard he would blow sawdust from his father’s saw mark.

He learned the wooden boatbuilding trade from his father, Edgar, and his father’s boatbuilding partner, Ned Hudgins. Most of his life, Diggs built wooden boats of some kind. After retiring from building commercial fishing boats in the late 1990s at Horn Harbor Railway, he built boat models and flat-bottom and deadrise skiffs in his garage at his home in Redart, Va. Late in life, he took up the game of golf and was darn good.

His boatbuilding legacy will live on for generations as anyone with knowledge of Chesapeake Bay wooden deadrise boats will certainly confirm that Edward Diggs built some of the prettiest, sturdiest workboats on the bay. Always a gentleman, soft-spoken, and always taking time to talk, he welcomed any arrival to his boatshop or at his home in a kind and friendly way. Amen!