Commodores Boats in Richmond, British Columbia, has been repairing boats for over 30 years, and the yard has seen some interesting projects. Last year, the crew sponsoned two boats, the Golovin Bay and the Sea Lady, at close to the same time using two different systems. According to Jake Spiller, the son of owner Bo Spiller, Commodores does most of its own design work and did so with the Golovin Bay, but they tried something new with the Sea Lady. “We used a designer who scanned the hull and created CAD files, and we sent those out to be cut. We like to try new things and hopefully improve our customers’ experience.”

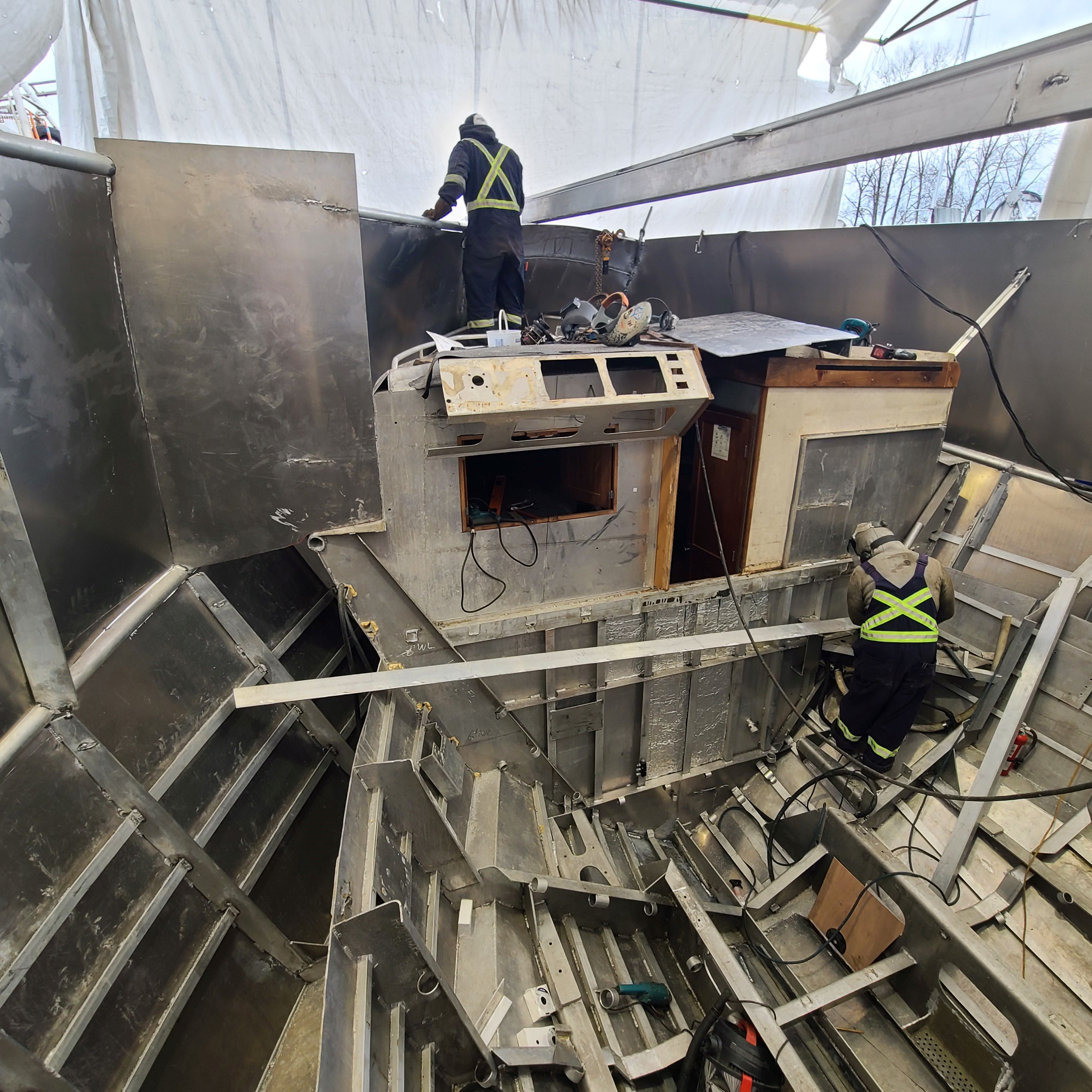

On the Golovin Bay, an aluminum crabber/longliner owned by Don Stiles in Nome, Alaska, the crew at Commodores did things the way they have on many previous sponson jobs, “Brendan Burgess ran that project. It was almost like building a new boat,” says 23-year-old Spiller. “We widened it by four feet on each side and stretched it out from thirty-eight feet to fifty. There’s not much of the original left.”

Don Stiles fishes red king crab in Alaska’s Norton Sound, and when working the waters around the waters of Little Diomedes Island, he is often just a few miles from Russia. “I fish the open access king crab fishery in Norton Sound,” says Stiles. “We’re allowed 40 traps and boats up to 50 feet.” It’s a race, Stiles notes, and he wanted the capacity to do better in it. “I’d been thinking for a few years about lengthening my boat, and then I saw one that Commodores had done, and I liked it. So, I called them up and they said they could do it, and the price was reasonable.” Stiles pulled the trigger, and the Golovin Bay arrived in Richmond in October 2022.

Commodores Boats’ standard process for sponsoning a boat is to initially widen the bulkheads so that the outer edges define a fair line from bow to stern—the Commodores crew then cuts and welds on the plate. Lengthening the boat adds an additional level of complexity to that process, as does working with aluminum. “With aluminum, we tack everything in place first. If you weld a long section, it pulls things out of place. So, we tack everything, and then when everything is lined up and tight, we start welding.”

The new design for the vessel raised the bow about 4 feet, according to Spiller. It also raised the deck and raised and expanded the wheelhouse. “If you look at the original and look at it now, they don’t look much alike,” says Spiller, noting that the new boat, with its elevated bow raked back towards the wheelhouse, draws a lot of attention and compliments.

“The one we did using the CAD files is similar. That’s the first one we did like that and it had its pros and cons.” Spiller explains that the project's workflow was affected by the delivery schedule of the parts but adds that the yard is planning to get its own CNC plasma cutter and will move more in that direction. “It does save more material because of how they can cut the plate,” he says. “And it’s great the way everything fits together.” He notes on the con side, though, that if things don’t fit, the fix can be time-consuming.

It’s a long way from Nome to Richmond and with his boat finally in a full-service yard, Stiles asked for more than just changes in the length and beam. “He had a pair of 300-horse Cummins’s in there,” says Spiller. “We replaced them with a pair of 650-horsepower Scanias. And added a 30kW Baudouin genset.”

The engines are set back aft of the hold, with wet exhausts. “They’re V-drives,” says Stiles. “So, the shafts are only about 8 feet long. The engines have ZF gears and the propellers are 31x30. I like the power I have now. During sea trials, we had her up to 16 knots. But I never go that fast. I run about 11 knots at 1150 to 1200 RPMs. That way I burn about 5 or 6 gallons an hour on each engine.”

Given his fishery and location, Stiles prefers twin engines. “I like the maneuverability you get. You can back one and go forward with the other. And I like the redundancy, in case one ever fails.”

Commodores also expanded the original hold and fuel capacities. “We added two tanks and raised the fuel capacity to 7,000 liters (1849 Gallons),” says Spiller. “And we expanded the hold capacity to 50,000 liters (1766 cubic feet).”

Stiles delivers his crab to a processing and freezer plant in Nome, and keeps his catch cool with a 7.5-ton refrigerated seawater system from IMS. “I got it in a trade and had it sitting around, so I put it in,” he says. “I’ll replace it eventually. It’s not really big enough for the size of the hold.”

Stiles has two cranes and a 4-foot-wide longline reel on deck, all hydraulic. “The halibut and black cod are down right now,” says Stiles. “So I’m not doing a lot of longlining. I have one Bigmax crane that’s rated for 1255 pounds when fully extended; it’s good for about 4,000 pounds when working in close. I have another Bigmax on the other side, and I put my crab block on that one. I got a new crane from China that is rated for 4,000 pounds. It arrived in August, but I haven’t had time to put it on yet.”

Stiles fishes 6-foot by 6-foot scissor pots he gets from Dungeness Gear Works in Arlington, WA. “They collapse down to about an inch and a half,” he says. “We were using the stacking ones, but these are a lot easier to work with.”

In the off-season, Stiles charters his vessel for research and carries freight. “I put cranes on both sides so I can load from both sides at the same time,” he says. He has crew quarters for six, with four bunks in the original hull, a stateroom with a full-size bed at deck level, and a daybed in the wheelhouse. “We’re going to redo the galley and add more counter space,” he says.

The new wheelhouse is well-appointed. Rigel Marine, in Richmond, BC, did the electric work on the Golovin Bay. “We did everything,” says Rigel Marine owner Anisur Khan. “The wiring and the wheelhouse electronics. It was about 90 percent new.” Khan supplied Stiles with a standard Furuno wheelhouse electronics package. “I the TZ2 Touch, and two 15-inch screens that display the radar, sounder, and plotter,” says Stiles. “It also gives me the option for camera views of the starboard side, back deck, and engine room.” Like so many Alaska boats operating in remote area, the Golovin Bay is also equipped with a Starlink satcom system.

Stiles took delivery of his virtually new boat in July 2023. “We’ve had some problems,” says. “The Mathers controls were slipping out of gear, the first propellers they had on it were the wrong size, and some other things, but that’s to be expected and we got it all taken care of. Overall, I’m happy with the boat Commodores delivered.”