Founded by longtime fisherman David O’Neill, Gannet Nets aims to provide premium gear by way of deliberate, data-driven development. Far from the bustle and board rooms of larger suppliers, O’Neill runs a three-person affair based on Washington’s Vashon Island with a focus on innovative gear for purse seining.

The birth of Gannet can be traced back 35 years to the beginning of O’Neill’s fishing career. That journey took him from his native Scotland to Norway and eventually to Alaska, where he cut his teeth as a crewman and sonar operator. He then spent several years at Seattle Marine and later a decade with Garware before founding Gannet Nets in 2010, which he now runs with the help of Matthew Camardo and Ezra Blake.

O’Neill said his company is very small next to industry’s major players, which allows him to work closely with fishermen and develop niche products that truly fit their needs.

“I’m a very small company in the scheme of things… I don’t have to answer to a board to justify anything. I’m focused on designing successful products, and it’s part of why fishermen enjoy working with me. They don’t sense that I’m after their last dollar,” O’Neill said.

Speaking from Louisiana, where he was field testing a new product, O’Neill said his process involves close contact with fishermen on the water, a relationship that stretches from inception to manufacture.

“Often my ideas come straight from the fishermen. Captains are full of them, but they don’t usually have access to someone like me that can make it happen,” he said.

Once an idea hits the water for testing, Gannet leverages aggressive data collection to refine the efficiency of his products.

“I use net sensors, and I use data to base my decisions on where I’m going with a design. That’s helped me a lot, and I don’t see anyone else doing it,” O’Neill said.

Another secret to O’Neill’s little guy approach is strategic manufacturing collaborations with industry mainstays like Garware, Duralite, Asano, Itsaskorda and Fluoron. It all adds up to a suite of one-of-a-kind products.

“I have some very unique products that have been in the field long enough under real conditions that I can say they have proved themselves. I’m the only place you can get these products,” O’Neill said.

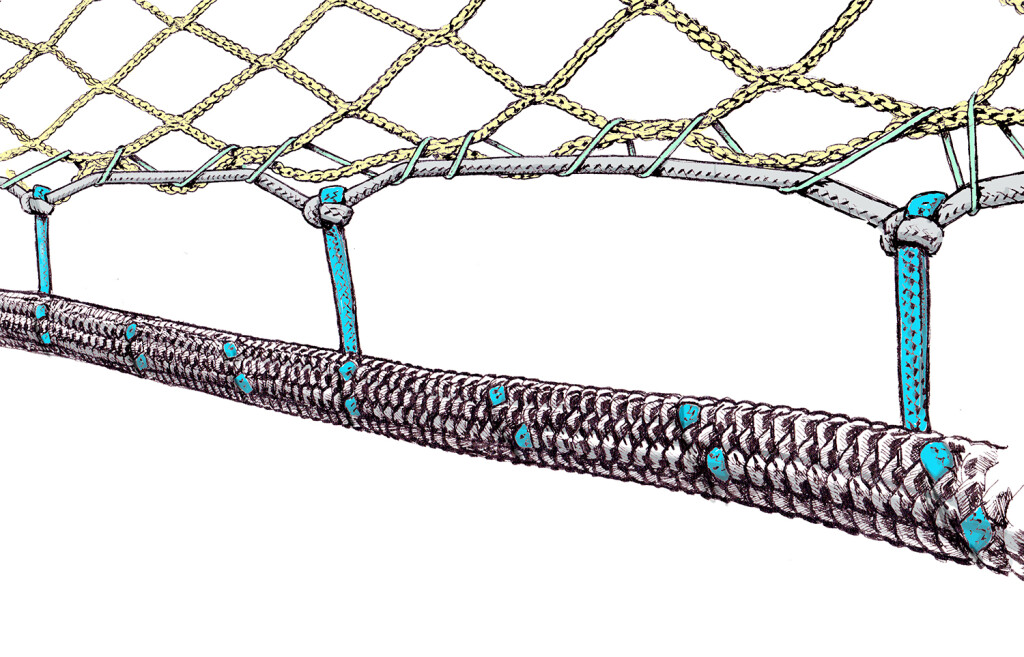

Among Gannet’s proven products are high-performance seine webbing containing some materials that O’Neill introduced to the Alaska seine fleet while he was working with Garware. In partnership with Spain’s Itsaskorda, Gannet has also developed new cork and leadlines that use ultrahigh molecular weight polyethylene, along with other materials. The corklines are so strong that O’Neill had to make new corks to match their strength.

“The weak part was becoming the float itself. So I worked with Duralite Industries to improve the floats, and now I’ve got a better all-around setup, line and float,” he said.

Gannet’s other niche products include floating purse rings manufactured by Fluoron, a special awl designed to work on Gannet’s new lines, and a stainless steel needle that O’Neill made in collaboration with the Japanese stainless steel masters at Asano.

“The needle is tool that I take with me everywhere. Everybody who uses one, buys one,” O’Neill said, adding that it provides unprecedented seizing strength when used with UHMWPE line.

And while O’Neill’s strong line of products have built him a following in the industry, he is far from done. He is out testing and developing constantly, and has a host of products in the pipeline that he hopes to roll out on the coming months.