Marine manufacturing giant MacGregor is moving toward electric deck equipment, including fully electric deck packages.

“We want our customers to have the convenience of a single control system, says Nils Arne Øksenvag, head of sales and tendering in the fishery and research division at Macgregor.

“Electrically driven deck machinery delivers the benefits of reduced energy consumption and lower maintenance requirements, significantly less noise, more precise control, while also removing the risk of leakage from high-pressure hydraulic drive systems,” states the Macgregor literature.

Now a global company, MacGregor has been building equipment for the marine industry since 1929. In 2017, the company expanded its offerings to the commercial fishing industry by acquiring the Rapp Marine Group for over $16 million.

Rapp MacGregor electric winches are well known in the US fishing industry and are used on vessels such as the O’Hara Corporation’s trawler Araho. Built with 10 to 110 tons of pulling power, the winches utilize several smaller motors instead of one large motor. “This provides effective redundancy in addition to decreasing weight, reducing inertia, and delivering more responsive control,” says the literature.

According to MacGregor, the redundancy for a four-motor trawl winch will be as high as 70 to 80 percent if one of the motors fails.

“There are no show-stoppers,” says Øksenvag. “If a motor breaks down, you can keep fishing.”

According to Øksenvag, the most exciting new tool in the MacGregor lineup is the company’s new fish pump for small pelagic species like herring and sandlance. “It’s made in 16 to 20-inch diameter,” says Øksenvag. He reports receiving positive feedback from the vessel owners using the pumps. “And from the market,” he says.

“The buyers of the fish say they are the best quality, and they are paying one or two NOK (Norwegian Krona = 10 cents) more per kilo. I know that one or two does not sound like much, but with the amount of fish they catch it becomes a lot,” says Øksenvag.

“Both the pumps, the 16-inch, and the 20-inch, use a fluid-cooled electric motor; it’s the exact same motor we use on our winches,” says Tommy Fagertun, one of the Macgregor engineers who has been working on the pumps since 2019.

“The electric motor is controlled by a frequency inverter that allows very accurate and precise control of the motor. The operator has full control over the RPM and load of the motor and pump impeller,” Fagertun says. “The frequency inverter is continuously monitoring the motor and keeping the speed constant no matter if the load varies. This is what separates the electric pump from a hydraulic one and provides our customers with better fish quality.”

Fagertun points out that the entire unit, including the motor, is submerged during operation. “The pump is designed to withstand 100 meters,” says Fagertun, noting that the pump is liquid filled, with no air inside that could be compressed.

MacGregor’s engineers are continuously improving every aspect of the pump system, Fagertun reports. “There have been some issues with saltwater ingress in the motor on some of the pumps, which could be due to a variety of reasons,” he says. “Recently, we finished a re-design/upgrade on the bottom compartment, which should greatly improve the ability to keep seawater out.

The pumps use an ROV-type (remote-operated vehicle) cable to supply power and communication, and the ROV cable can also be used to lift the pump, Fagertun explains. “But so far, most customers lift it with an additional wire from a crane,” he says. He adds that the communications wiring in the ROV cable allows for monitoring of depth, temperature, pump pressure, and other variables.

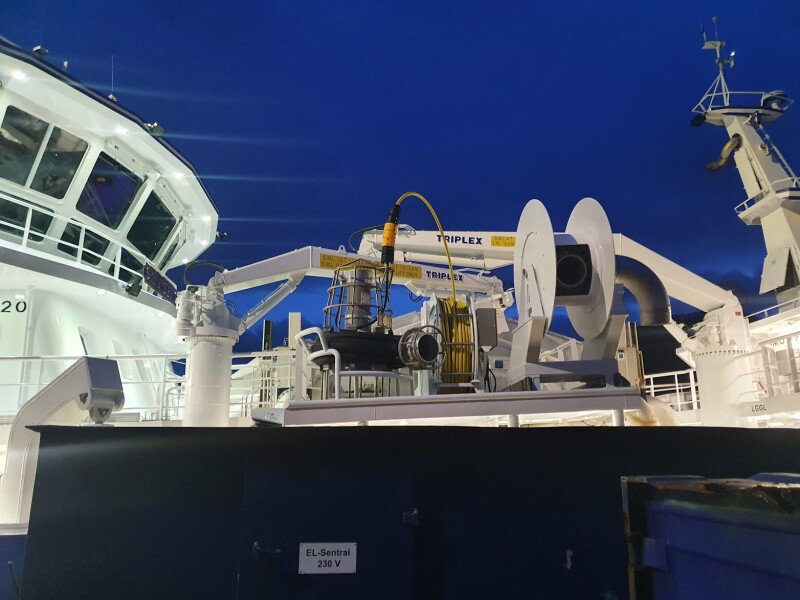

While Rapp makes the winches and fish pumps, another MacGregor company, Triplex, will make the cranes. Both companies started working together on the complete electric package before MacGregor bought them.

“MacGregor is always looking into developments, and the continuous improvement of their portfolio, and are also looking into developing an electric crane,” says Øksenvag. “But so far, fishermen are skeptical. If the chief engineer is familiar with hydraulic, they want it,” he says. “But we think that when they try the electric crane, they will appreciate its responsiveness and the quiet.”

According to Fagertun, the engineering team is investigating the best solution to create a fast, compact and rugged deck crane. “I cannot say exactly when they will be introduced; we will have to make a prototype and do some proper testing first.”

Øksenvag notes that with an all-electric deck machinery package, vessels will lose the noise and vibration of hydraulics. “We had one skipper tell us that with his electric package, the boat was so quiet that they only heard the noise from the sea, the noise of the waves on the vessel.”