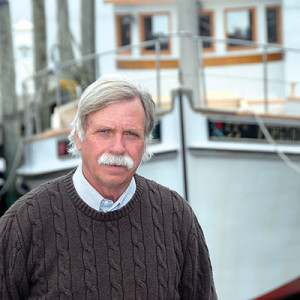

Nathan Everett of Still Kickin’ Seafood in White Stone, Va., uses every square inch of his 1991 model Parker 25 to crab pot, gillnet and dredge for oysters in Chesapeake Bay.

In April, Everett and crew were crab potting when his Yamaha 250-hp outboard with 8,000 working hours on the engine blew up, requiring a tow home.

Everett purchased a new 300-hp four-stroke outboard from Jett’s Marine in Reedville, Va., and Lee Haynie of Bull Neck Marine in Reedville installed the engine. With the 300-hp outboard, Everett has picked up 15 percent better fuel consumption and 3 more knots in speed. “With the new motor, we can fish two more 1,200-foot gillnets in a day than we could with the old engine,” says Everett.

As a young boy, Everett started his commercial fishing career on the Pamlico River in Beaufort County, N.C., working on a crab boat. He eventually got his own boats and moved to fishing in the Atlantic Ocean and Carolina Sounds out of Hatteras Village, N.C.

Some years later, he met his future bride in Virginia and moved from offshore Carolina fishing to inshore Chesapeake Bay fishing. As part of that move, he left behind a 42-foot fiberglass vessel built by Provincial Boat & Marine Ltd. out of Kensington, Prince Edward Island in Canada. He still owns the boat and has someone fishing it in North Carolina waters.

With the move to the Chesapeake, Everett had Tim Cahoon of Belhaven, N.C. modify the Parker 25. The modification included installation of a used Privateer center-console wheelhouse; modification of the stern and bottom, originally designed for inboard/outboard power; and raising of the ceiling (floor) inside the boat. A Stainless Marine motor bracket was installed to extend the engine aft to provide maximum work and gear space inside the boat.

The 25' x 9.5' x 2' Parker has a gillnet reel mounted at about amidships and an aluminum bowpicker extending from the bow. On a day fishing this spring, Everett and crew caught 10,000 pounds of menhaden. “She was loaded down to the gunwales, but she brought us home,” he says.

Everett does his own maintenance on the boat by hauling it out at Robbins Boat Yard’s boat ramp located next door to Still Kickin’ Seafood’s crab house. “We just pull it out on a trailer, put her up on the hard, and take care of the maintenance,” says Everette. “She is a lot easier to maintain than the bigger boats that I have owned.”

Moving to Deltaville, Va., we announced the retirement of 84-year-old boatbuilder Lewis G. Wright of Deltaville in the October ’86 NF Around the Yards. Wright learned to build wooden boats from his father and three uncles who were pioneers in the development of Chesapeake Bay deadrise and cross-planked wooden boats at the turn of the 20th century.

Wright’s cinderblock boatshop on Jackson Creek in Deltaville, with its sweet aroma from heart pine wood chips, linseed oil and copper paint, has long since been replaced with a fine waterfront home.

Wright’s boatbuilding legacy, however, lives on in Deltaville as boatbuilder John England of Urbanna, Va., and the Deltaville Maritime Museum continue to build Lewis Wright style skiffs in the museum’s boatshop.

Inside the museum’s shop in June, a 19' 8" x 6' 2" x 18" Lewis Wright deadrise style skiff was nearly complete. The museum uses the new boatshop to provide a cultural experience for visitors and as an outlet to sell skiffs when completed.

This new skiff is the third one at the museum’s boatshop that has been built in stages. The skiff is built out of Georgia heart pine, white cedar and pressure treated wood.

Keel, stem and stringers are built out of pressure-treated wood; chine log, timbers and transom from heart pine; and bottom and side planks and removable floorboards from white cedar. The floorboards and entire inside of the skiff are coated with a mixture of turpentine and linseed oil. “This is easy long-term maintenance,” says England.

The deadrise bottom is made from two layers of white cedar planks laminated with epoxy. The bottom is coated with Pettit Hydrocoat 1640 Red Ablative Antifouling paint, and a semi-gloss white latex paint is on the sides. The boat is fastened with 3/16" stainless bolts and stainless nails.

Inside the skiff, a riser strip attached to frames holds seats or can be used to tie down side bumpers. The skiff will be powered by a used 65-hp outboard Suzuki engine, and when completed will be on the market. This is the second Lewis Wright style skiff built by England. The first skiff was based on a Willard Norris style.