On a 2019 visit to Port Townsend Shipwrights Co-op, I picked up a T-shirt with the image of a bandsaw on it. I wondered, why not a ship? But the saw turned out to be a symbol of how the founding shipwrights started the business.

“In 1981 about six or seven guys bought a planer and a ship saw from a shop that was going out of business,” says Jeff Galey, one of the dozen current member-owners of the co-op. “It’s our logo.”

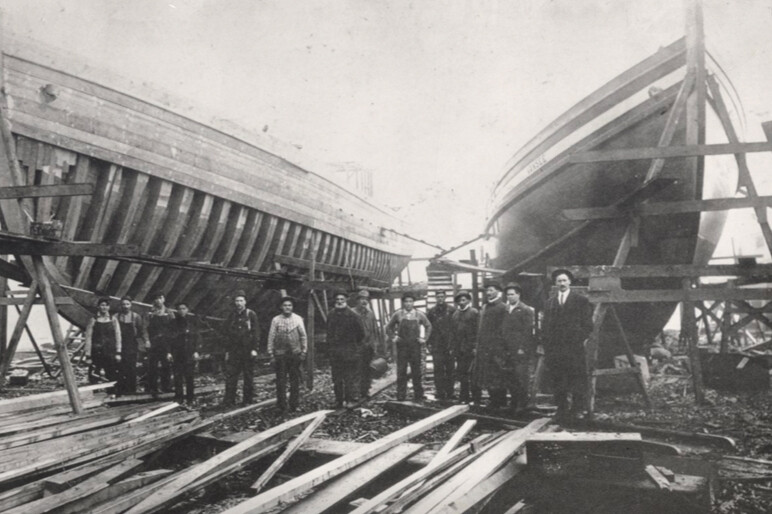

The saw came from the Western Boat Co., which was co-founded by Joe Martinac, who later started the Martinac Shipbuilding Corp. The Western Boat Co. operated from 1916 to 1982 and built the Western Flyer — a purse seiner made famous when it carried writer John Steinbeck on a journey that he wrote about in “The Log from the Sea of Cortez” — that is currently undergoing a major rebuild at Port Townsend Shipwrights. “You could almost call it a new build,” says Galey. “I think it has about 12 pieces of the original wood.”

According to Galey, the founding members built a timber frame building around the already antique machinery and launched an enterprise that has lasted 40 years and continues to grow.

“Currently we are 12 member-owners and 50 employees,” says Galey. “We had buildings on land we leased from the port. The original members built a second timber frame and then a steel building. But it was very spread out. Around 2014 or 2015, we gave our old buildings to the port and built a 30,000-square-foot building that we can drive the 300-ton lift into.”

The shipwrights have now consolidated operations in a cluster of buildings between Route 20 and Port Townsend Bay. And the yard is full of boats of all types and sizes, but covid-19 has affected business.

“We usually get calls for commercial fishing boats in September,” says Galey. “But we didn’t hear from them until starting in January. Lots of longliners from Seattle.”

Besides the Western Flyer, the co-op had worked on some of the most iconic wooden boats in West Coast fisheries, doing everything from major conversions to general maintenance.

“We had the Polaris here,” says Galey, “She’s a first time customer. And the St. John II, they’re a regular return client.”

The 73-foot halibut schooner Polaris was built in 1913 by John Strand in Seattle and is still fishing 108 years later. The 65-foot St. John II, built at Hansen Boat Yard in 1944, and owned by Gary Olsen and his son Peter, splashed back into the water in February of this year. After spending the late winter and early spring fishing for blackcod and halibut, she heads for Alaska.

“We’ve gone to Port Townsend about for about 10 years,” says Laurie Olsen who runs the family’s You Are What You Eat Fish Co. “They put a new engine in a few years back. They redid all the finish woodwork in the galley, new freshwater tanks, new generator. They’ve replaced planks, and they replaced the bow stem last year. They did such a nice job, we decided not to paint it. They just put a clear coating on it, though they painted it this year.”

Olsen, an art school graduate, makes an added contribution. “When they get done, they let me go paint the name on the boat,” she says.

On its website, the co-op features photos of the St. John II getting a new deck in 2013. The co-op’s crew took off the original deck from 1944 and laid in new larch decking that they then corked (caulked) and sealed with pitch. The 77-year-old vessel is still going strong, providing fresh fish to local consumers, and breaking in a new generation of fishermen.

“I’m trying to get people to realize how delicious blackcod are,” says Olsen. “Everyone wants halibut. The last trip, they headed in, and I sold over half of it that night.”

Besides Gary and Peter on the boat, Olsen also lets her 14-year-old son go out to learn the ropes. “His name is Raymond, after his grandfather who bought the boat. We also have an 11-year-old daughter. She doesn’t go yet, but she wants to. She puts on her oil gear and helps clean the boat when it comes in.”

Another vessel that’s regularly under the care of the shipwrights, is the Carol M., owned by the co-op’s receptionist, Diana Clausen and her husband, Mike. “We bought the boat in December 2008,” says Diana Clausen. “She was built in 1926 by O.E. Moberg.” The Carol M. is 62 feet long, with a 15.4-foot beam, and a draft of 7.9 feet, and Clausen believes every inch has had something done for it at the co-op.

“We started bringing her here, even before I started working here,” she says. “This place is a one-stop shop, so every year we tackle a big project. This year we’re refastening the starboard side. We did the port last year, and they put in about 17 or 18 ribs.”

Jeff Galey recalls they also had to replace a plank just below the turn of the bilge and take off a few more above the deck. “We had to take off six or seven to get the ribs in,” he says.

According to Galey, they sistered the existing ribs, steaming the new 3- by 4-inch ribs in alongside them. “She was originally fastened with galvanized nails. The planking is about 2 inches thick, and we’re using number 18, 4-inch screws.”

The yard also worked with IMS to install a blast freezer in the Carol M. And mechanics Todd Lee and Walter Trisdale have kept the old 350-hp John Deere chugging. “Walter did a massive overhaul on it a few years ago, and Todd has dropped everything to come fix it on at least two occasions,” says Clausen. “There are very few things that need to be done that can’t be done here. And owners can work with the professionals, at their skill level of course. And if you have a question, the level of knowledge here is outstanding.”

That is no accident, according to co-owner Galey. “We went out and found good leaders,” he says. “We look for people with different skills to lead on projects,” he says, noting that each project has an owner assigned to it, depending on the nature of the work. “It energizes everyone when we bring someone new in and hear new ideas.”

The owners meet every Tuesday to schedule work and assign workers to projects. “We do heavy woodwork. We also have a finish wood shop,” says Galey. “We have a machine shop with a 90-ton press break. We have electronics, we can make hydraulic hoses, and we just bought a sail loft.”

Galey allows that they do contract out some work. “We can do fiberglass here,” he says. “But we sometimes contract that out — and sandblasting. We just did the Shandalar, a 70-foot steel boat from Seward. He runs her as a tender sometimes, and also fishes blackcod, halibut and crab. We got everything ready, and then a company came over from Seattle and sandblasted her in about a day and half.”

Switching boats from longline to pot fishing has provided work for the co-op as fishermen in Alaska struggle to keep sperm whales from stealing their fish.

“Whales are smart,” says Galey. “They hear the hydraulics start up, and they know.” Conversions usually entail installation of heavier reels and hydraulics to handle the pots. “We don’t know how to manage the whales,” says Galey. “We installed a sounding device on one boat, to scare them off. But it didn’t work.”

But consistent with the company’s band saw logo, the Port Townsend Shipwrights Co-op is most famous for keeping wooden boats alive. “We’re starting to get boats from Seattle Terminal,” says Clausen, referring to the 108-year-old Polaris. “It’s amazing that these boats are still viable, and that we have the skilled people to keep them fishing safely.”

Galey notes that there is a handful of other shipyard co-ops. But Port Townsend Shipwrights Co-op stands out as a yard that is bringing young people into the trade and expanding.

“Twenty-five percent of our employees are women,” Galey says. “Looking forward, we want to grow.”