You can tell a healthy fishery when people are building new boats for it, and the Atlantic scallop fishery fits solidly in that column. Nordic Fisheries, the company that Roy Enoksen started in 1968 with the purchase of the venerable Sea Trek, is now in the process of replacing much of its extensive fleet. The latest addition, the 85-foot F/V Heritage, came out of Junior Duckworth’s yard, Duckworth Steel Boats, in Tarpon Springs, Fla., in early February 2021.

Junior Duckworth watched boats being built as a kid.

“There was a yard near where I grew up where they were building wooden boats, steaming the ribs in and all that,” says Duckworth. But when he got out of the Army in 1965, he went to work building steel boats at a local yard. “I learned a lot, and worked my way up,” he says, and in 1978, he launched his own company.

Duckworth builds his steel boats the old-fashioned way, stick built, fitting and cutting each piece of plate onto the frames.

“It takes a little longer, but you don’t waste as much material,” he says. Maine-based naval architects Farrell & Norton send Duckworth a set of offsets, and he lofts them full-size in a roofed section of his yard. Duckworth takes the three-dimensional shapes of the frames off the two-dimensional loftings, the same as the wooden boatbuilders he watched as a kid. “I do it the way we’ve always done it. I’m too old to learn all the computer stuff,” says Duckworth, 78.

The vessel’s full dimensions are 85 feet long, with a beam of 28 feet, and a draft of 9 feet. With the frames set up and faired, Duckworth’s crew begins sticking on the plate.

“We built the hull out of A36 steel,” says Duckworth. “We use 3/8ths on the bottom and sides up to the main deck, quarter-inch on the wheelhouse except in the front where the waves hit. Where the dredges land on deck can be as much as an inch thick, and along the sides where the dredges come banging up is 3/4.”

Duckworth figures the Heritage is the 15th boat he has built for Nordic Fisheries over the last 10 years. He runs a crew of around 15 welders, fitters, electricians, and mechanics, more when he’s building two boats at a time.

“I like to keep things small,” he says. “That gives me more control over things. The most we ever built was three at a time, but I was a lot more agile then.”

Besides his crew, specialists from New Bedford, Mass., such as Tony Vieira of TK Electronics and technicians from Marine Hydraulics, travel to Florida to install equipment. “They come down, and some of our guys will help them,” says Duckworth.

The hull is pretty much a standard scallop boat. Measuring in at 85 feet, the owners skipped putting in a bow thrusters. What’s new is that instead of outriggers and birds, they opted for wing stabilizers from Marinexpert Plus in Gaspe, Quebec, to help give the crew a more comfortable and steady work platform.

“They start just above chine and then go under from there,” says Duckworth. “A lot of guys are going that way. It’s less maintenance. You don’t have all those extra cables and losing those birds all the time.”

The wing stabilizers came at the recommendation of the architects, notes Peter Anthony, a co-owner of Nordic Fisheries.

“They give us a more stable platform.” The wings extend from below the water line on the hull and can be raised up when at the dock. “There’s less rigging,” says Anthony. “And they work in both directions, where the birds only really work when they’re being pulled up.”

Trying something else new, the crew of the Heritage can sort and bag scallops in the 28' x 24' x 8' hold. “They have a 4-inch pipe in the shucking house, and scallops go down into a big vat. They got a tumbler down in the fish hold to separate and wash them. Then they bag them and ice them,” says Duckworth, noting that, like most scallop boats, the Heritage will use ice to keep its catch fresh.

“Actually we can do it either way, in the hold or on deck,” says Anthony. “It’s a quality consideration, especially in the summer. With the wash tank in the hold, near all that ice, it stays cooler. Once the scallop comes out the shell, the closer it is to the ice, the better.”

Forward of the fish hold sits the Heritage’s powerhouse, an 800-hp Cummins QSK38. A 65-kW John Deere runs the hotel and electronics, and a 450-hp Cummins drives all the hydraulics. The main engine has a 6:1 Twin Disc MGX 5321 DC reduction gear that turns a 6-inch-diameter Aquamet 17 shaft.

“That shaft is 36 feet long,” says Duckworth. “They have a 69-inch propeller in a Todd Horn-built nozzle. Todd’s over in Bayou la Batre [Ala.]. He does real good work.”

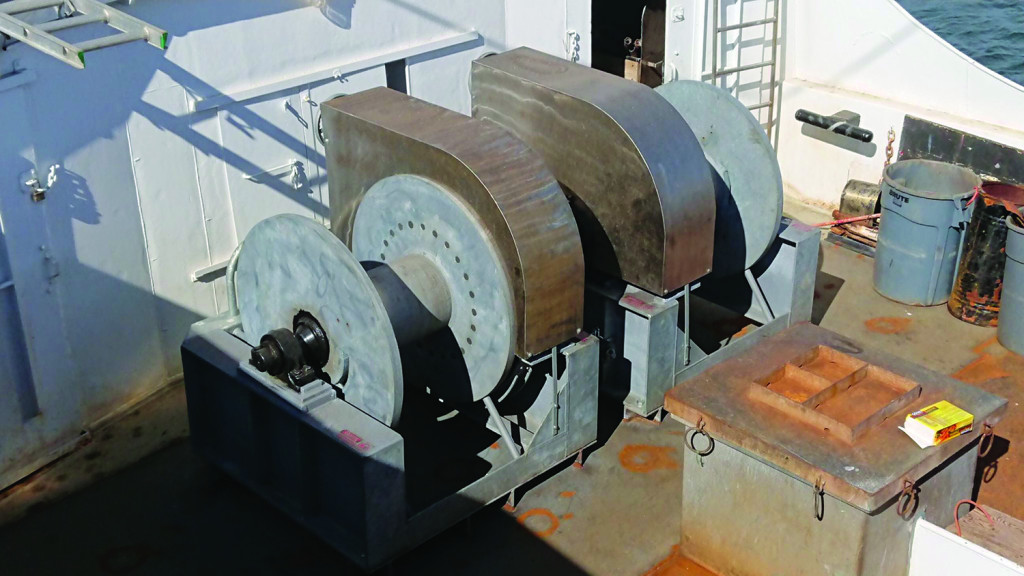

All the winches on the Heritage are hydraulic. “The main winches, the lifting winches, take-out winches and the stabilizer winches,” says Duckworth, “all hydraulic. They have electric back-up to run the hydraulics. In case anything happens, they can get their gear back.”

According to Jacob Enoksen at Marine Hydraulics New Bedford, the main winches and lifting winches are manufactured in-house and shipped to Duckworth Steel Boats for installation.

“We make them here,” says Enoksen. “We use Hägglunds drives; they’re direct-drive, 30,000-pound maximum line pull on a bare drum.”

The shucking boxes, a key feature on any scalloper, run fore and aft under the wheelhouse. “The shucking boxes are just about 10 feet long,” says Duckworth. “They have air conditioning and a sound system in there.”

Crew accommodations consist of two four-person staterooms, one on the main deck, one down below, forward of the engine room, and a stateroom for the captain. While crews are limited to seven people, the boat may sometimes carry observers.

“Farrell and Norton draw the lines for the galley, where they think things should be, but then the owners usually make changes,” says Duckworth.

The wheelhouse above the galley and staterooms, has a basic electronics package installed by Tony Vieira of TK Electronics.

“I went down and did it all in six days,” says Vieira. “I have to go back and take care of a couple of things.”

The package includes a Furuno depth sounder, two Furuno radars, two Simrad GPS units, a weather station, a Furuno satellite compass, Intercom, two Icom VHFs, AM/FM audio, a Furuno AIS, and a Timezero bottom builder.

According to Anthony, the intent was to build a small and simple vessel.

“We were limited to 800 horsepower,” says Anthony, referring to the upper limit of a Tier III engine. “We didn’t want to build too much boat, but we wanted to make sure we had the bollard pull we needed, so we went with 85 feet. There’s a lot of boats here in New Bedford that are that size. They get the job done.”

In the interest of simplicity, Nordic Fisheries made a number of design choices. In addition to the simpler wing stabilizers, they opted out of a bow thruster.

“We come and go out of New Bedford 90 percent of the time, and there’s plenty of room in this harbor,” says Anthony, pointing out that only one of the company’s boats has a bow thruster.

The Heritage was expected to make the voyage from Junior Duckworth’s yard to New Bedford in late March and begin fishing in the spring.

With Nordic and other New Bedford scallopers constantly improving the harbor’s fleet, and healthy scallop resources to support their efforts, Duckworth is looking forward to building more boats for the fishery.

Inside the F/V Heritage

Home Port: New Bedford, Mass.

Owner: Nordic Fisheries

Builder: Duckworth Steel Boats, Tarpon Springs, Fla.

Hull material: Steel

Year built: 2020-21

Fishery: Atlantic scallop

Length: 85 feet

Beam: 28 feet

Draft: 9 feet

Propulsion: Diesel

Engine: Cummins QSK38 800-hp

Power train: Twin Disc MGX5321dc at 6:1; 6-inch diameter Aquamet 17 shaft; 69-inch propeller in nozzle

Hydraulics: Cummins 450-hp drive pump for all winches

Fuel capacity: 13,500 gallons

Speed: 12 knots top, 9 knots cruising

Hold capacity: approximately 240,000 pounds

Crew accommodations: 9 bunks

Electronics: Furuno depth sounder, 2 Furuno radars, 2 Simrad GPS units, a weather station, a Furuno satellite compass, intercom, 2 Icom VHFs, AM/FM audio, a Furuno AIS, and a Timezero bottom builder

Deck gear: Main winches, lifting winches, take-out winches and stabilizer winches built by Marine Hydraulics in New Bedford, Mass.