Oxe outboards has muscled its way into the workboat market, but outside of aquaculture, the company has yet to make a sale to commercial fishermen.

“Fishermen don’t like the price,” says David LeBlanc, regional sales director for Oxe. “We’re working with crabbers here to help them see the savings in fuel and maintenance. We’re talking to jig boats and red snapper longliners. Our other distributors are working with fishermen on the West Coast. There’s interest.”

At around $50,000 the Oxe diesel outboard is a big investment compared to comparable gas engines, and the diesels are heavier.

“The 150-hp and the 200-hp are about 200 pounds heavier than gas engines that size. The 300-hp is about 150 pounds heavier,” says LeBlanc, who contends that the benefits of the Oxe engines more than compensate for the price and weight considerations. “It’s out-performing other engines in its class in every metric: durability, speed, load capacity, you name it,” says Leblanc.

Oxe is upping its game in the United States with a new manufacturing plant and dealer training facility in Albany, Ga.

“We’re just getting started,” says LeBlanc. “Right now we’re manufacturing the 125-, 150-, and 200-horsepower engines. The 300 is coming next.”

As yet, commercial fishermen haven’t bitten on the Oxe, but the engines are selling strong in a number of workboat markets. Penn Cove Shellfish, an aquaculture company in Washington, chose Oxe for several reasons.

“We saw an Oxe diesel outboard displayed at the Pacific Marine Expo and admired the belt drive and heat exchange cooling,” the company said in a statement. “We know that diesel engines have more torque and last longer than similar gas engines and the Oxe brand has engines available in the horsepower range [125-300] that we use, so it appeared to be a perfect fit for our needs.”

Another European engine company, Bourdeaux, France-based Nanni, has been building marine engines since the 1950s, but has only found its way into commercial fishing hulls primarily in the last decade. Distributed by Kraft Power, Nanni marinizes a variety of engines.

“Nanni marinization is simply the best,” says Brook Streit, in charge of distribution of in the Northeast.

“We specialize in marinization,” says Streit. “Up to 150-hp, they’re all Kubota based, and then from 200 to 400 hp are Toyota based. Then we have a gap while we work things out with John Deere. We sold at least 70 John Deere based engines in Maine alone, but right now we can’t import the John Deere based motors,” he adds, noting that Nanni and John Deere are renegotiating their arrangements. “From 600 to 1,150-hp are all Scania based.”

Streit is working with engine installer Roger Kennedy in Stueben, Maine, to put an 800-hp Nanni N13 900 into a Maine lobster boat, the Alison Jo.

“I love it,” says Alton Wallace, owner of the Nanni-powered, Alison Jo, a 40-foot H&H that he finished in his own shop. “You can feel how smooth it runs,” says Wallace. “At 2,300 we topped 29 knots. At 1,730, we cruise at 19.”

Nanni engines meet all EPA standards, Streit points out, but the company is working on diesel-electric hybrids. “For commercial applications, we partnered with Transfluid on an inline hybrid system. We have a number of projects that we’re working on. They’re not all public yet, but we got some neat stuff going on.”

According to Streit, the smaller Nanni engines in smaller boats offer the best numbers for efficiency.

“If you look at the amount of diesel burned to make a Tesla battery, it would have to last a lot longer than it does to make it green, in reality. We see guys with smaller boats, like 28 feet, using small engines like the Nanni 270-hp inline 4-cylinder. There’s not a cleaner way to produce propulsion power than these small diesels,” he says.

Paul Hebert, one of the stars of the TV show “Wicked Tuna,” also bought a new H&H 40-footer. Hebert put a Volvo-Penta 625-hp D11 into his new boat, the Wicked Pissah.

“I signed for her on December 26, 2018,” says Hebert, with the boat ready to launch in Milbridge, Maine, in early June. “We’re going to Gloucester,” he says. “Believe it or not, she’s going in the water tomorrow, and we’re leaving as soon as we get the electronics done.”

MAN engines are powering more small boats in the United States and Canada, and the company is developing hybrid systems for various fisheries.

“We got a request from the lobster industry to boost up speed to the fishing grounds and then go all electric,” says Juergen Haberland of MAN. “I can’t give the detail, but the talks are under way. We are starting with small boats, around 50 feet, and then we will work our way up, 80, 100, 150 feet. We also have a request from a trawler in Canada.”

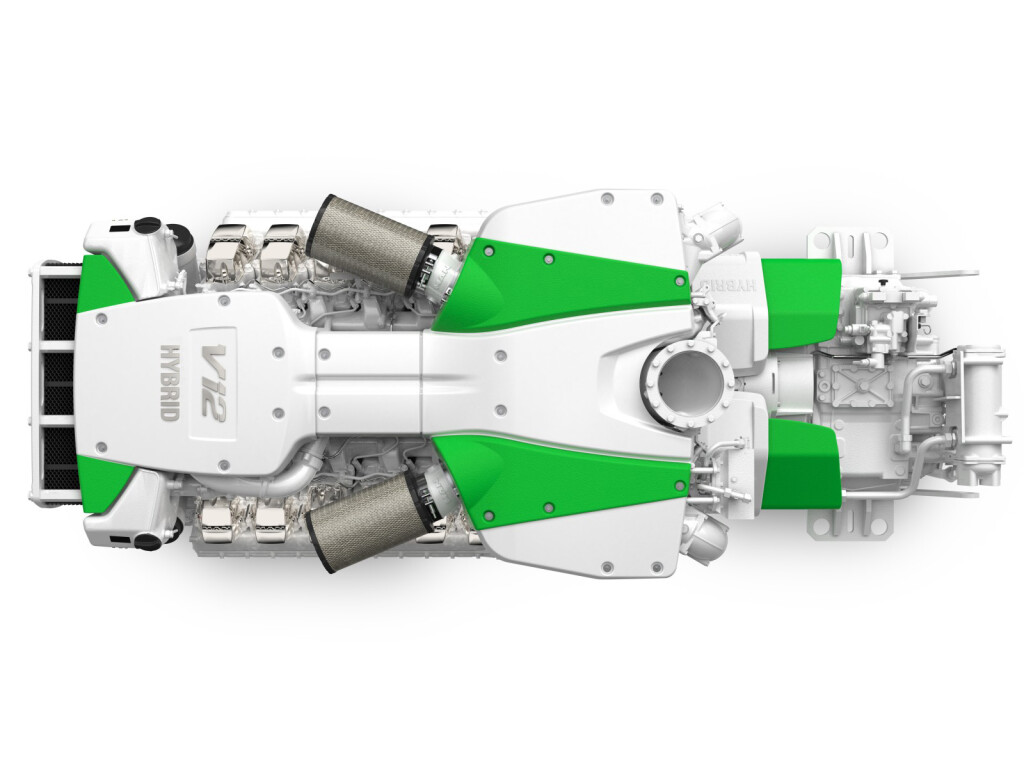

The MAN hybrid system will be a parallel system primarily for dual engine installations.

“You will be able to put additionally to each prop system 200 to 400 kW [286 to 536 hp],” says Haberland. “Then you can drive in four to five different modes — diesel only, electric only, both, and cross over between the engines. You can also run all the hotel’s systems, so it’s very flexible.” According to Haberland, MAN is working with Volkswagen on technology aimed at increasing battery life, charging speed, and power density.

Besides hybrid electric, MAN is also working with alternative fuels, including compressed natural gas, liquefied natural gas and hydrogen. While LNG is not practical for small boats, Haberland believes CNG may have some potential, as well as hydrogen.

“They have less power density, but they are cleaner,” he says.

For boats that are running bigger diesels, MAN’s SCR system has been very successful.

“We have years of experience with aftertreatment technology,” says Haberland. “Ours is comparatively compact and lightweight, also it’s modular. We don’t offer one box, we have modules that anyone can put together in a given installation space.”

The Finnish company Wärtsilä is on an aggressive path toward decarbonizing marine engines through electrification, engine optimization, and alternative fuels. The drawback of alternative fuels is that their volumetric energy density is lower than that of diesel fuel, and consequently they require bigger tanks.

With space at a premium on fishing boats, engine optimization, often augmented by some version of electrification, might seem like the most attractive option. But the Norwegian company Sorheim Holding is building an LNG-powered trawler/seiner, the Selvåg Senior. The 260-foot Skipsteknisk-designed boat will be powered by an LNG-fueled, 6,437-hp Wärtsilä 8V31DF engine.

With the LNG stored at minus 140 to minus 160 degrees C, designers integrated a cold recovery system for the RSW in the 2,480-cubic meter fish hold.

Every engine company has its strategy and market, and Mitsubishi is betting its chips on the simplicity number.

“There are two advantages to Mitsubishi,” says Doug Oehrlein, sales and marketing consultant at Mitsubishi Turbocharger and Engine America. “One is big displacement. We typically have 20 to 25 percent more displacement than our competitors. I think that translates into longevity. The second thing is mechanical advantage, especially if they’re fishing in remote waters where you can’t get a mechanic out there with a computer.” Oehrlein notes that on the displacement, a Mitsubishi will be 15 liters but have the same horsepower as the competition’s 13-liter engines.

“We just build bigger, heavier engines,” he says, but points out that fuel consumption is comparable. “And our customers tell us that with a screwdriver and a wrench, you can get a mechanical engine going,” he says.

Oehrlein reports that Mitsubishi has the fastest-growing sales on the Gulf Coast, and sales to longliners working out of Hawaii, as well as to many Alaska fishermen. New Bedford scallop fleet owner Lars Vinjerud put a big Mitsubishi S12R in his newest boat, the uniquely designed Viking Power, built at Williams Fabrication in Bayou La Batre, Ala., in 2020. Pot cod fisherman Buck Laukitis also put a Mitsubishi in his new Fred Wahl 58-footer, the Halcyon.

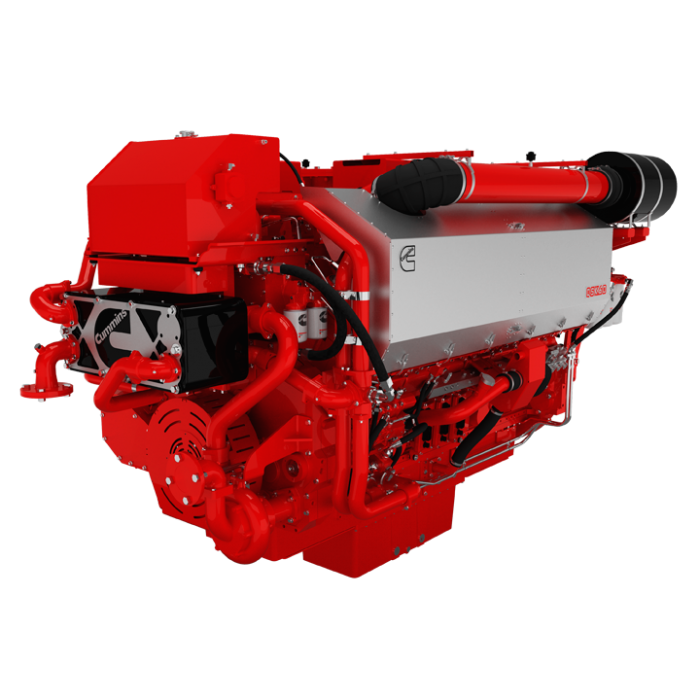

The other big names in diesel are introducing their premier products. The latest Cummins QSK60, providing 2,155 kVA/1,724 kWe of power, went into the Calvert, a 243-foot, Skipsteknisk-designed factory trawler built in Tersan, Turkey, for Ocean Choice in Newfoundland.

In 2020, John Deere introduced a new PowerTech 4045SFM85 marine engine.

“The engines’ high power-to-weight ratio delivers impressive torque in a compact package, making it an ideal choice for planing and semi-displacement hulls,” according to the company. “The 4045SFM85 marine engine has two ratings (M4 and M5) — 205 kW (275 hp) at 2,600 rpm and 235 kW (315 hp) at 2,800 rpm. These ratings are ideal for light-duty commercial vessels.”

On the opposite end of the scale, Caterpillar bought EMD from Progress Rail almost a decade ago and marinized what had been primarily a train engine. The EMD E 23 engine is an option for large freezer trawlers — newbuilds or repowering. The two-cycle engine can be configured in 8 to 20 cylinders and deliver 2,000 to 5,000 bhp at 900 rpm. It meets Tier 4 final standards and has a natural gas option.

At Cascade Marine in Seattle, Tim Sandeman has put engines in about half a dozen Bristol Bay boats for the 2021 season.

“A couple of Scanias, 750-hp keel cooled. People like the power-to-weight ratio,” he says of Scania’s 13-liter powerhouse. “We’re working on another 800-hp with a heat exchanger. People are looking for performance, they want to get up and plane with 4,000 or 5,000 pounds of fish. We can get that extra horsepower with the heat exchanger. The Scania DI13 87M is the one with the heat exchanger, the keel cooled is the DI13 088M.”

Sales of Yanmar engines have slowed for Sandeman, but only because his market is satiated. “We sold a lot of Yanmar 350-hp, V-6s for the bowpickers up in Cordova and Copper River,” he says. “All those boats are engined up now.”

The marine diesel world is an active place as manufacturers increase power and efficiency while beginning to explore alternatives.